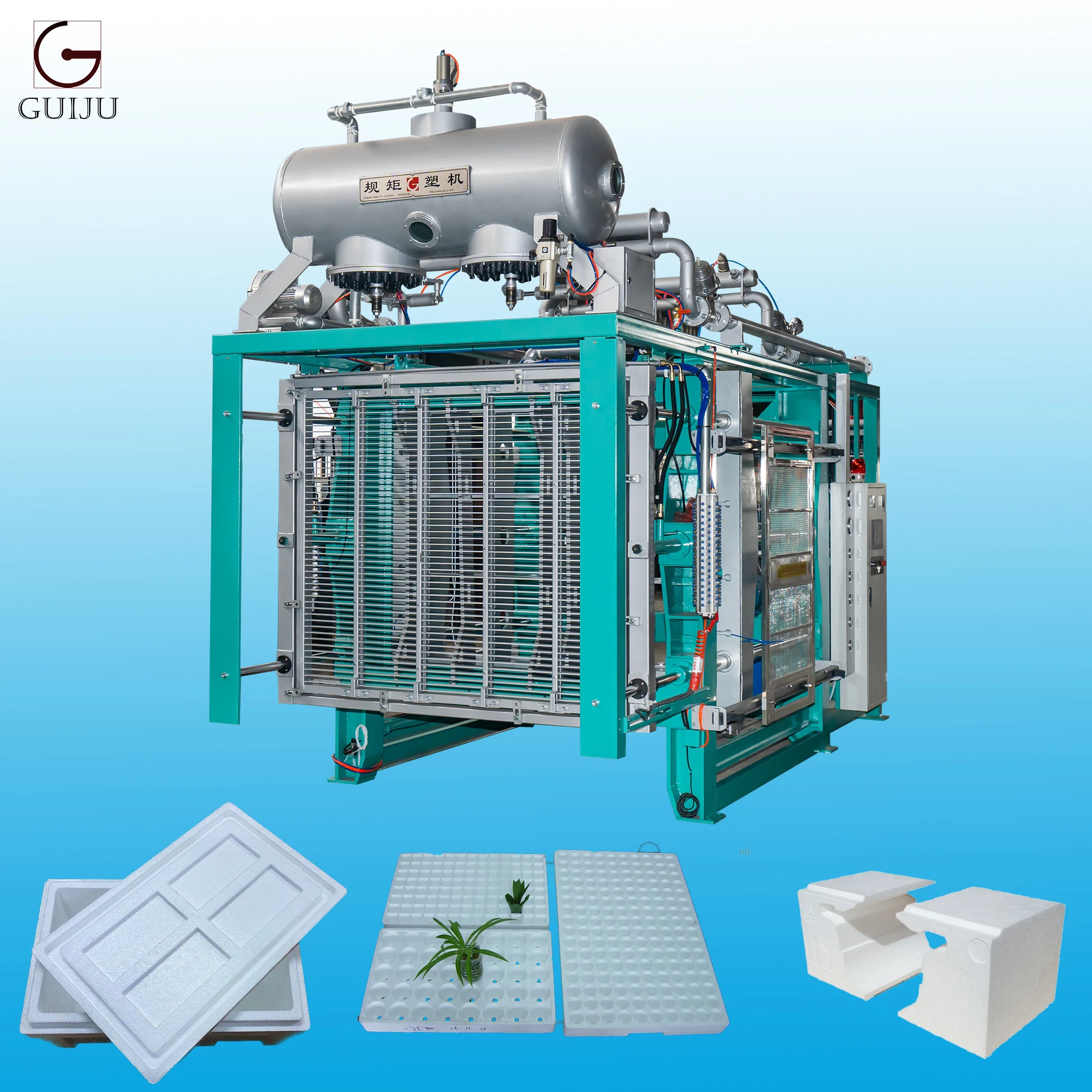

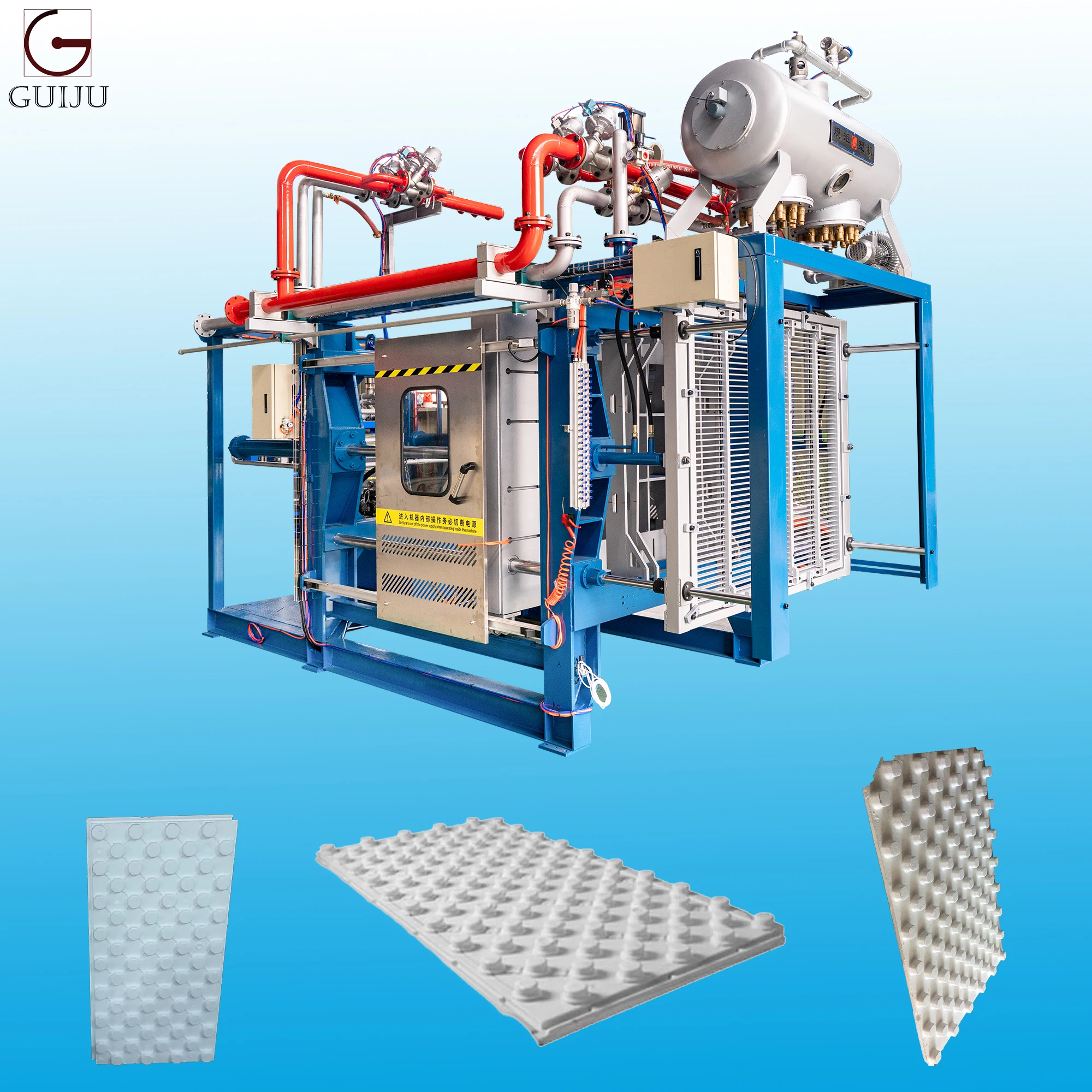

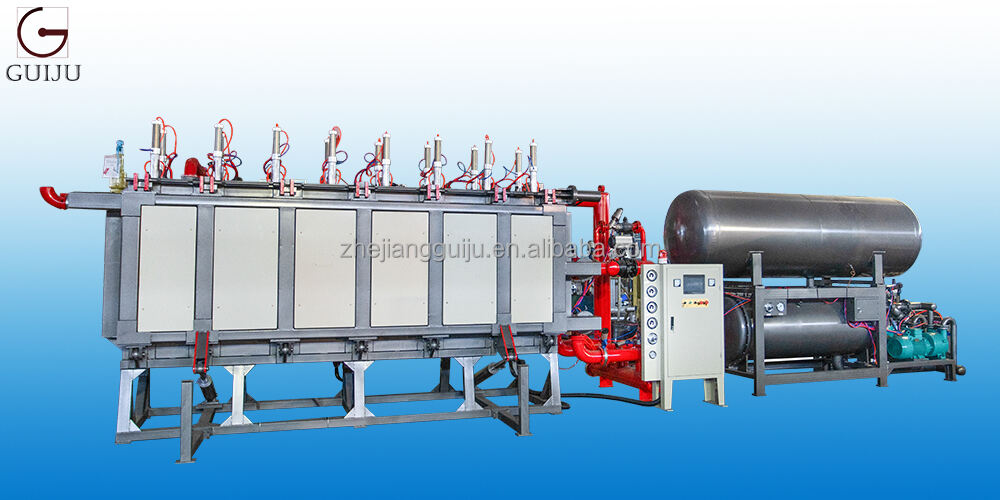

Automatic Expanded Polystyrene Vacuum Cooling EPS Block Moulding Machine EPS Panel Sheet Making Machine Board Production Line

- Overview

- Recommended Products

Guiju

Introducing the Automatic Expanded Polystyrene Vacuum Cooling EPS Block Moulding Machine EPS Panel Sheet Making Machine Board Production Line. This innovative machine is a game-changer in the EPS block molding industry, offering unmatched efficiency and quality in producing EPS panels and sheets.

This state-of-the-art machine is equipped with advanced technology that ensures precise molding and uniform cooling of EPS blocks, resulting in high-quality panels and sheets every time. The automatic process saves time and labor, making production faster and more cost-effective. Say goodbye to manual labor and hello to efficiency with the Guiju EPS block molding machine.

With its vacuum cooling system, this machine ensures rapid cooling of the EPS blocks, reducing production time and increasing productivity. The guiju EPS panels and sheets produced by this machine are lightweight yet durable, making them ideal for various applications such as insulation, packaging, and construction.

The Guiju EPS block molding machine is designed to meet the highest industry standards, ensuring consistent quality and reliability. Its user-friendly interface makes operation easy and intuitive, allowing for seamless production with minimal downtime. The machine is also energy-efficient, helping to reduce operational costs and environmental impact.

Whether you are a small business looking to expand your production capacity or a large manufacturer in need of a reliable and efficient machine, the Guiju EPS block molding machine is the perfect solution. With its versatility and superior performance, this machine is a must-have for any EPS production facility.

Invest in the Guiju Automatic Expanded Polystyrene Vacuum Cooling EPS Block Moulding Machine EPS Panel Sheet Making Machine Board Production Line and take your production to the next level. Experience the difference in quality, efficiency, and reliability with this cutting-edge machine. Order yours today and see the Guiju difference for yourself.

Automatic EPS block molding machine with vacuum cooling

Main feature:

model |

unit |

GJ-BZ-2000 |

GJ-BZ-3000 |

GJ-BZ-4000 |

GJ-BZ-6000 |

|||

mould Cavity Size |

mm |

2040*1240*1040 |

3050*1240*1040 |

4070*1240*1040 |

6090*1240*1040 |

|||

foam block size |

mm |

2000*1200*1000 |

3000*1200*1000 |

4000*1200*1000 |

6000*1200*1000 |

|||

steam system

|

inlet size |

mm |

DN100 |

DN100 |

DN150 |

DN150 |

||

inlet pressure |

bar |

5---8 |

5---8 |

5---8 |

5---8 |

|||

consumption |

kg/cycle |

30-50 |

40-70 |

55-85 |

70-130 |

|||

compressed air system

|

inlet size |

mm |

DN50 |

DN50 |

DN65 |

DN65 |

||

inlet pressure |

bar |

5-8 |

5-8 |

5-8 |

5-8 |

|||

consumption |

m³/cycle |

1-1.5 |

1.5-1.8 |

1.8-2 |

2-2.3 |

|||

injector sizeInjector

|

injector NO. |

8pcs |

10pcs |

16pcs |

22pcs |

|||

injector size |

DN80 |

DN80 |

DN80 |

DN80 |

||||

drainage pipe |

mm |

DN125 |

DN125 |

DN150 |

DN150 |

|||

vacuum drainage |

mm |

DN80 |

DN100 |

DN125 |

DN125 |

|||

condensation drainage |

mm |

DN100 |

DN125 |

DN125 |

DN125 |

|||

cycle Time (15g/l) |

min/cycle |

3 |

4 |

5 |

6 |

|||

vacuum pump power |

kw |

5.5kw*2 |

5.5kw*2 |

11kw*2 |

11kw*2 |

|||

installed Power |

kw |

20.5 |

22 |

33 |

33 |

|||

overall Size |

mm |

7500*3200*3500 |

5500*3200*3500 |

11000*3200*3500 |

13000*3200*3500 |

|||

machine weight |

kg |

6000 |

8000 |

10000 |

12000 |

|||