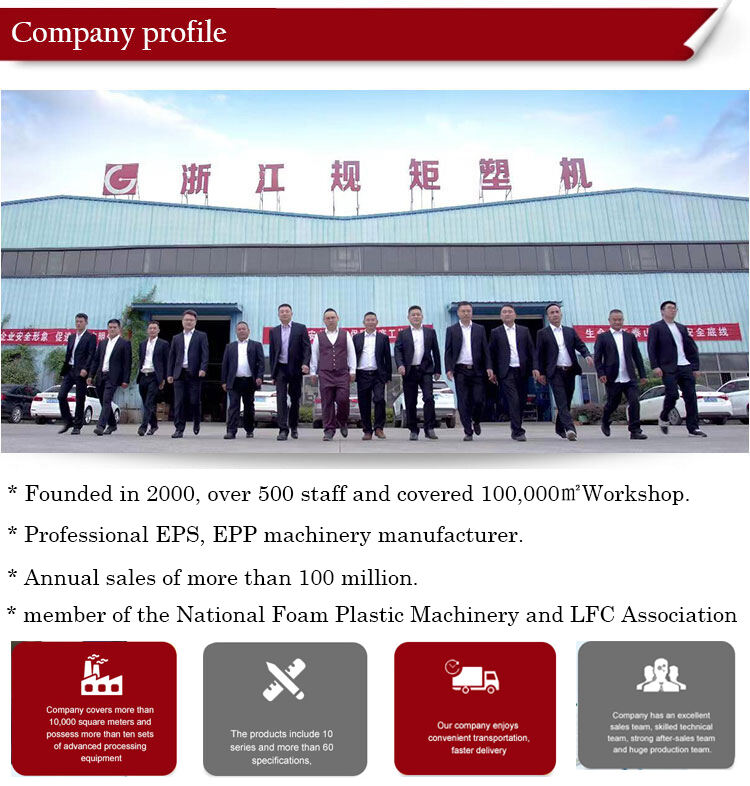

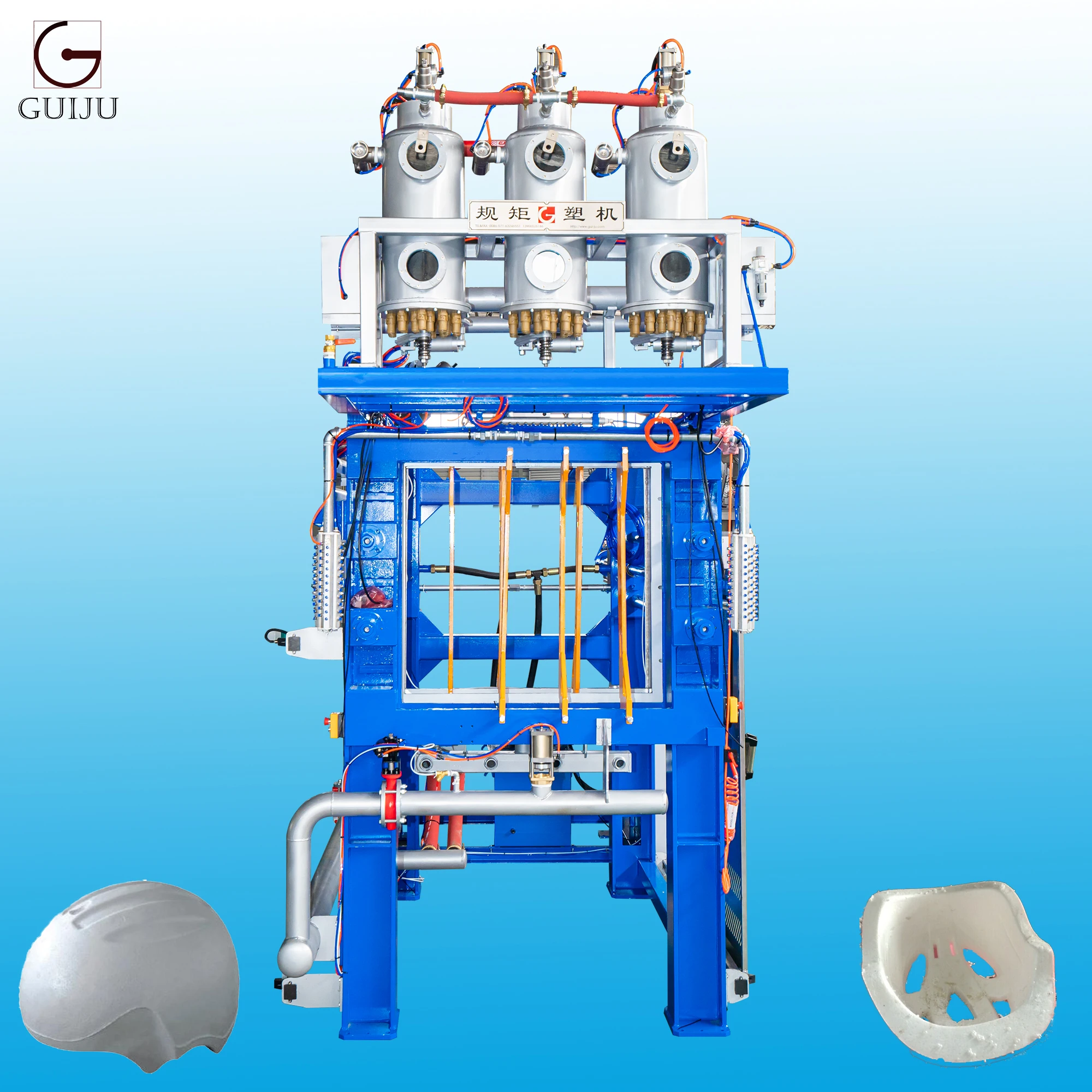

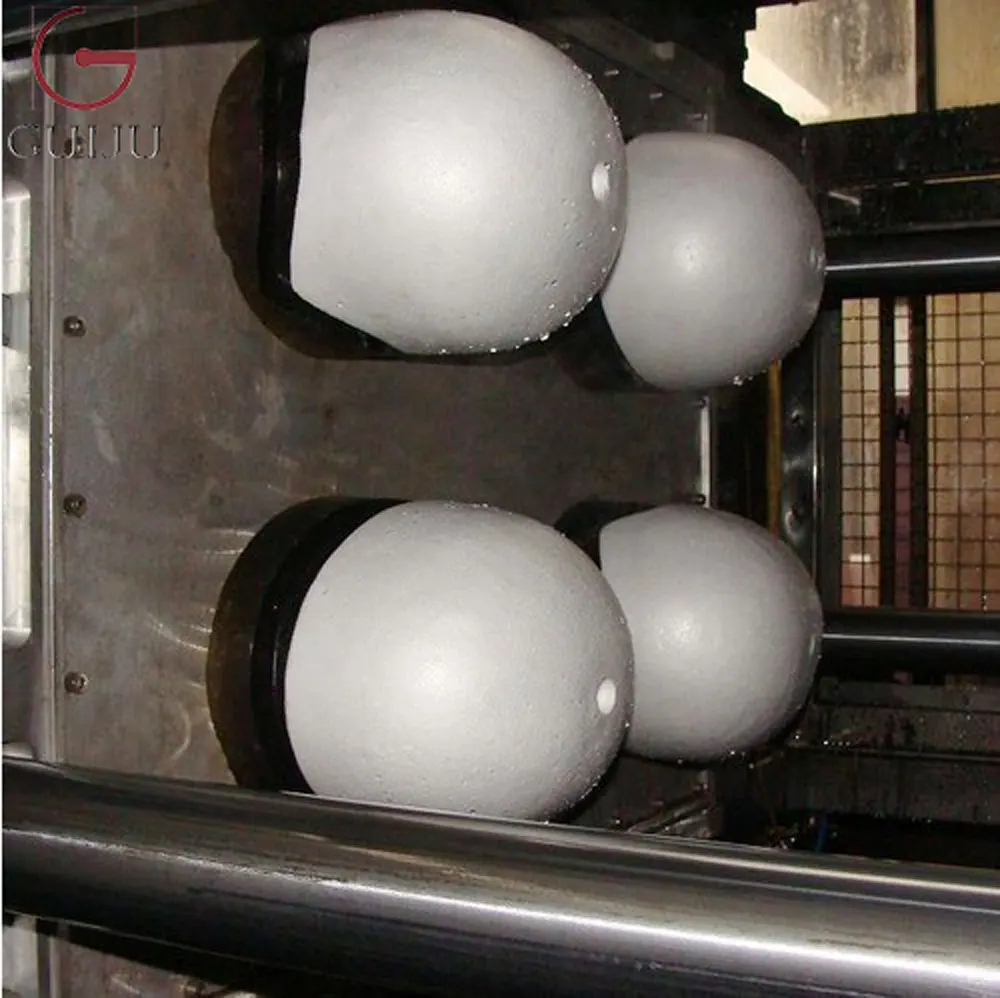

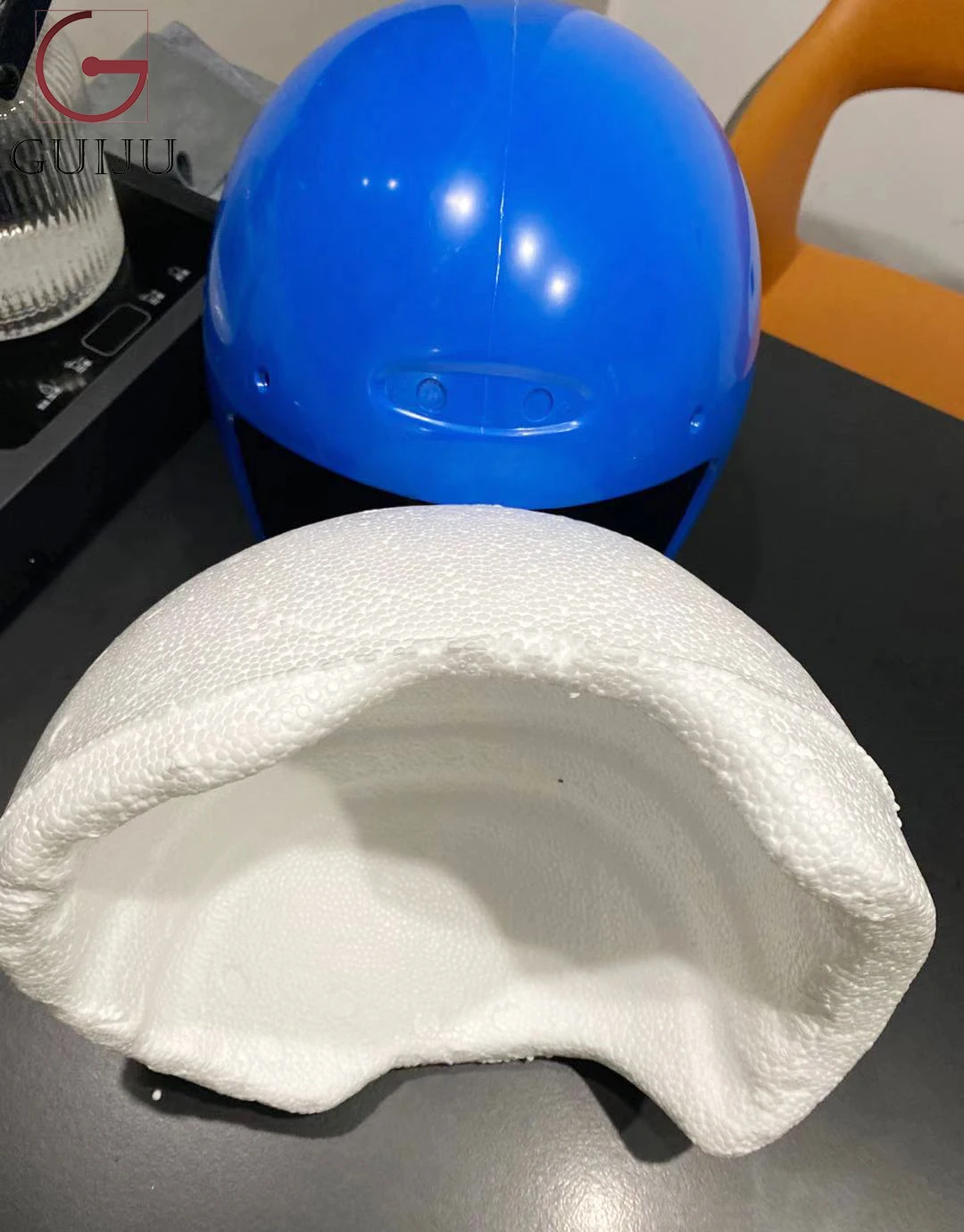

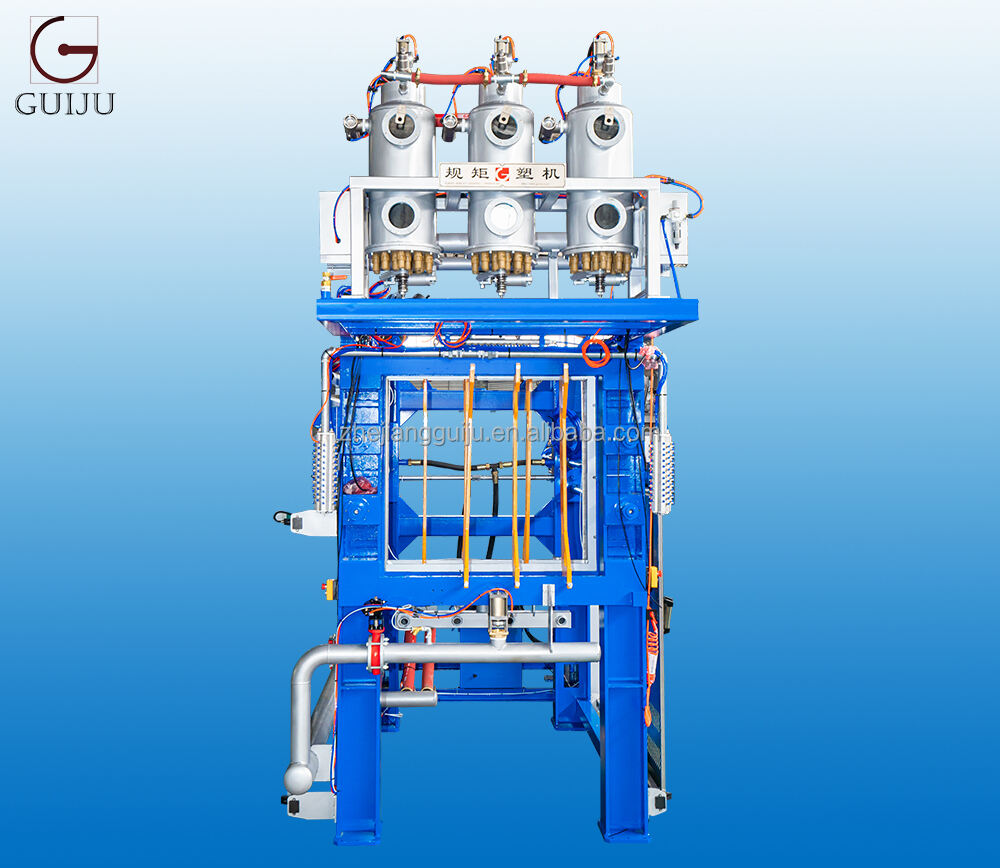

China eps foam machine manufacturer eps polystyrene foam helmet moulding machine foam helmet production line

- Overview

- Recommended Products

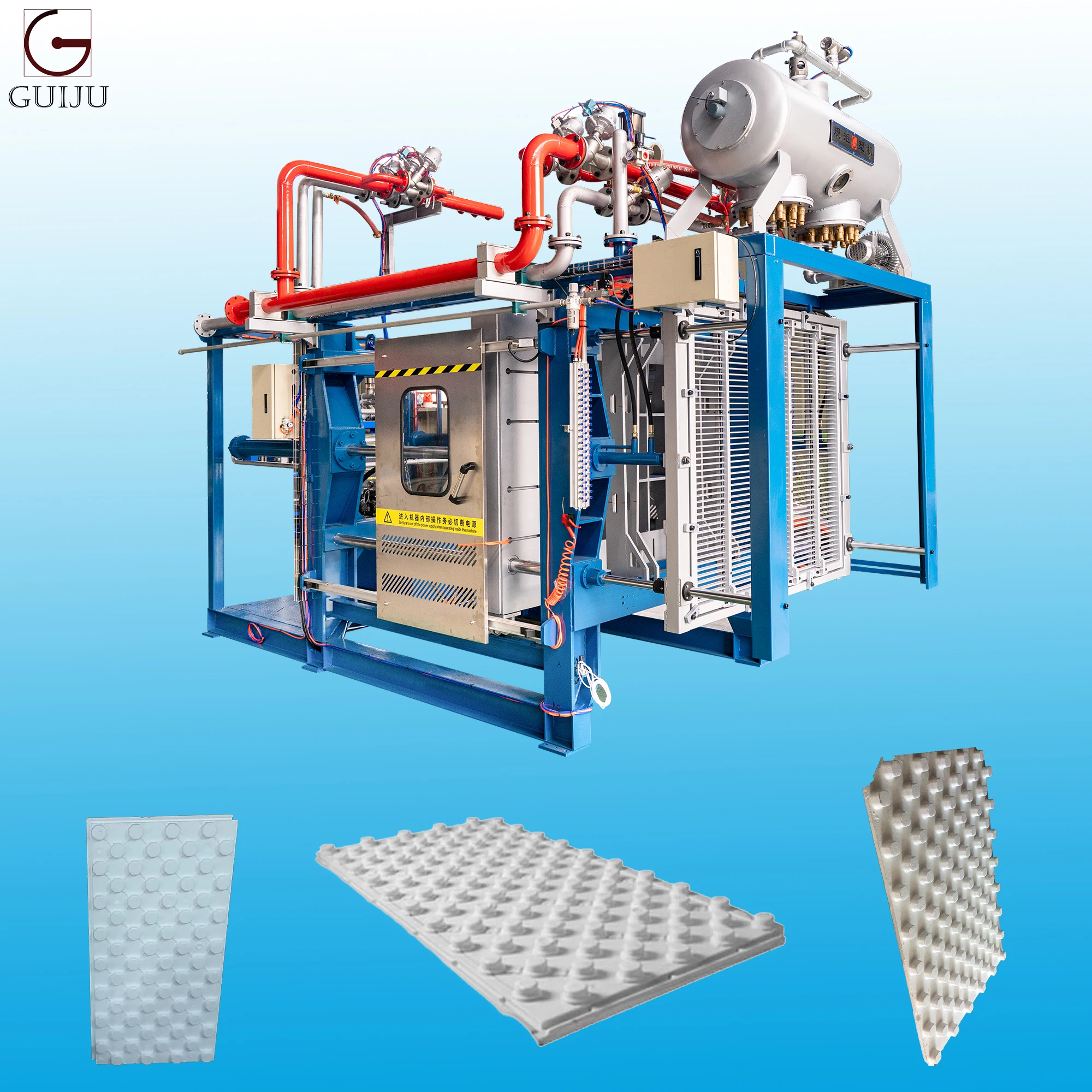

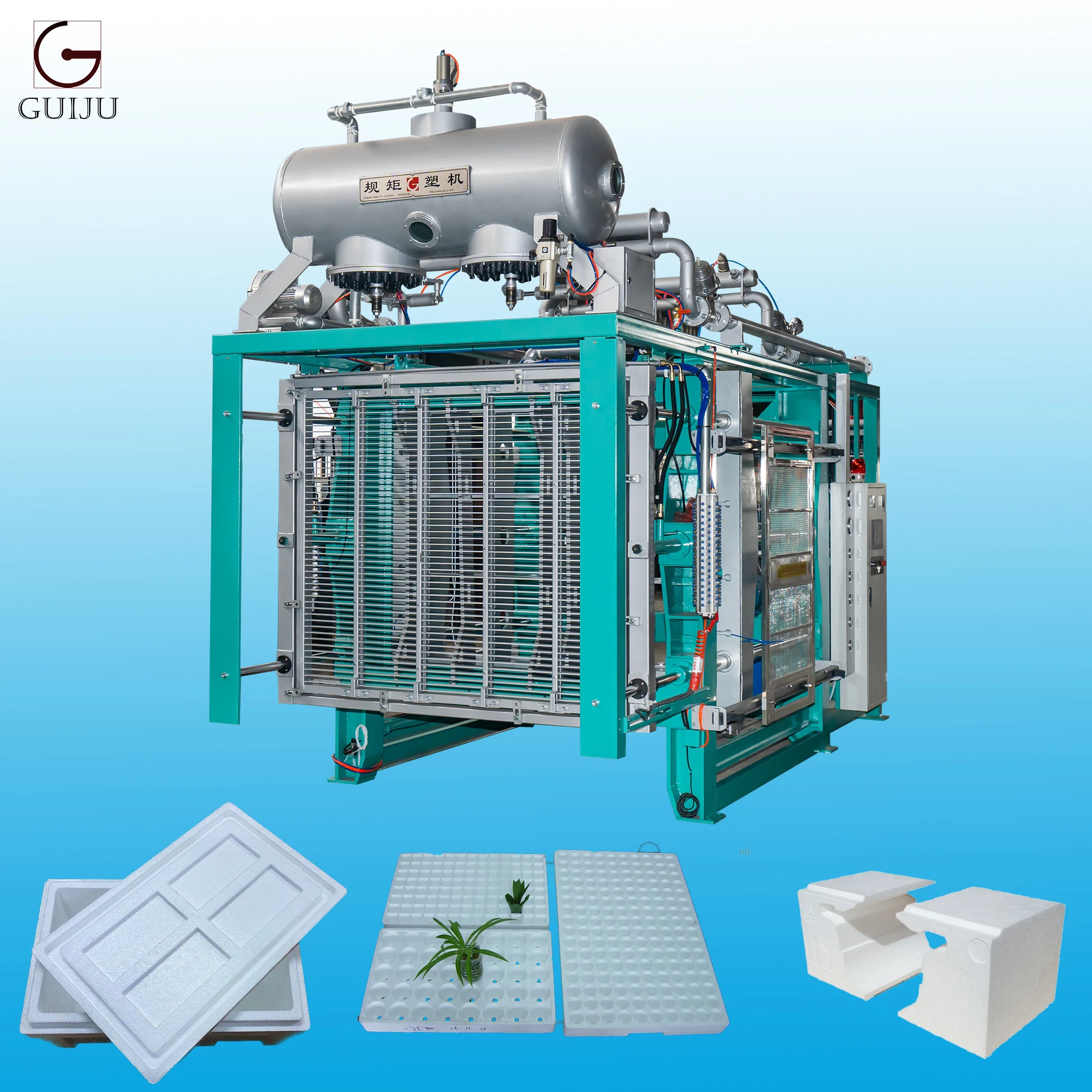

Top sales automatic eps shape molding machine with vecuum cooling

Main feature:

1. It is made of 16---22mm steel plate welded with carbon dioxide shielded welding. All templates are treated with high temperature tempering and high pressure shot peening, so it has high strength and high surface hardness; 2. The template is processed by CNC numerical control, after processing, the surface is sprayed with zinc to prolong the service life of the whole machine; 3. The hopper adopts horizontal or vertical double turntable, total have 44 pcs discharge outlet, can meet customer’s demand for multi-product, multi-filling gun; 4. It adopts the heating principle of low pressure and large flow, and with double steam valves, steam valve is controlled by balance valve and air control valve, make sure the steam pressure more precise.

Technical data

|

Subjects

|

Unit

|

GJ-TZC-1210

|

GJ-ZK-1412

|

||

|

Standard mould size

|

mm

|

1200×1000

|

1400×1200

|

||

|

Rear Window size

|

mm

|

1100×900

|

1250×1120

|

||

|

Max. finished product height

|

mm

|

300

|

300

|

||

|

Moving mold running max. speed

|

mm/s

|

200

|

200

|

||

|

Oil pump pressure

|

bar

|

100---150

|

100---150

|

||

|

Installation power

|

kw

|

11.7

|

13.2

|

||

|

Oversize(L*W*H)

|

mm

|

5250×2450×4000

|

5250×2700×4300

|

||

|

Machine Weight

|

Kg

|

around 5200

|

around 5800

|

||