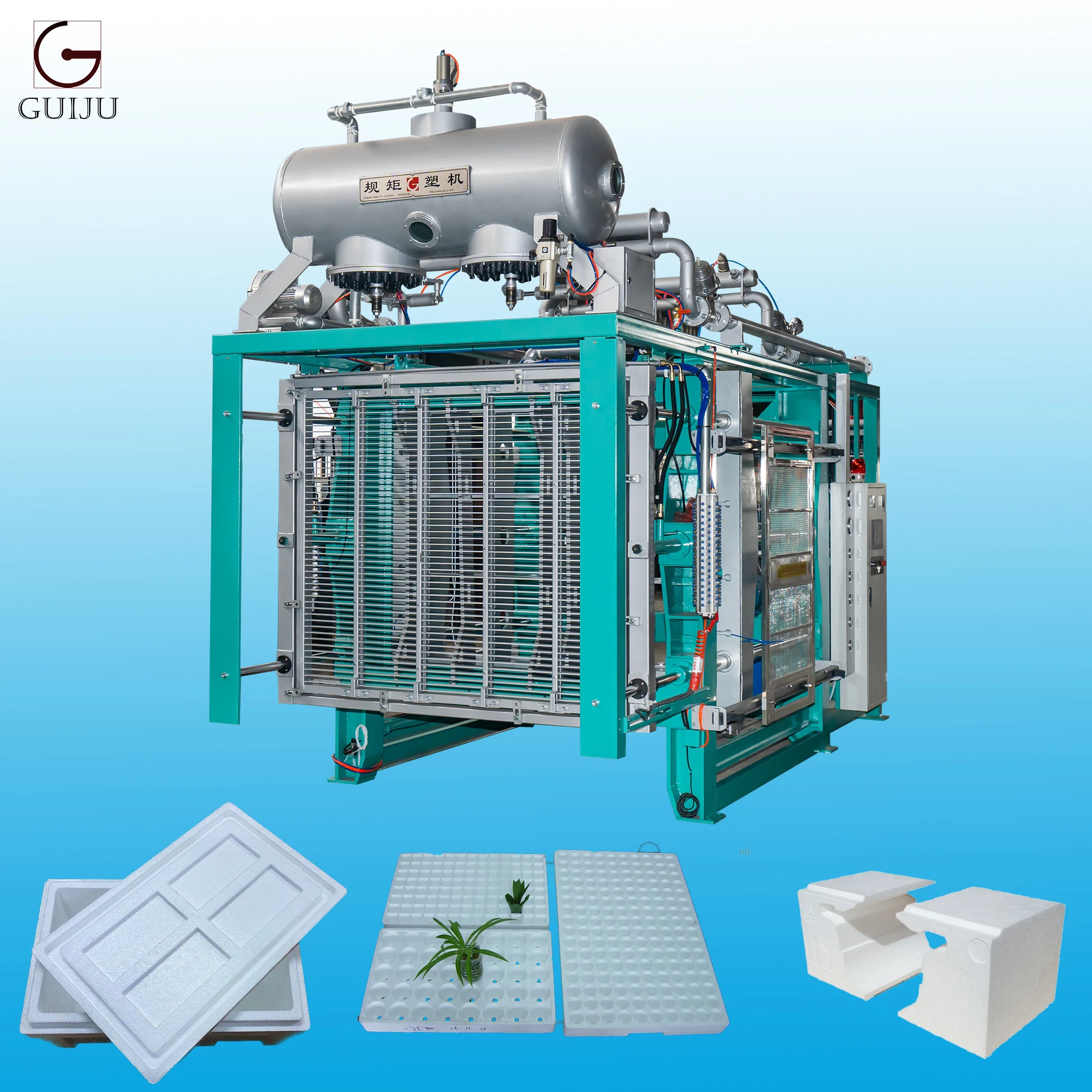

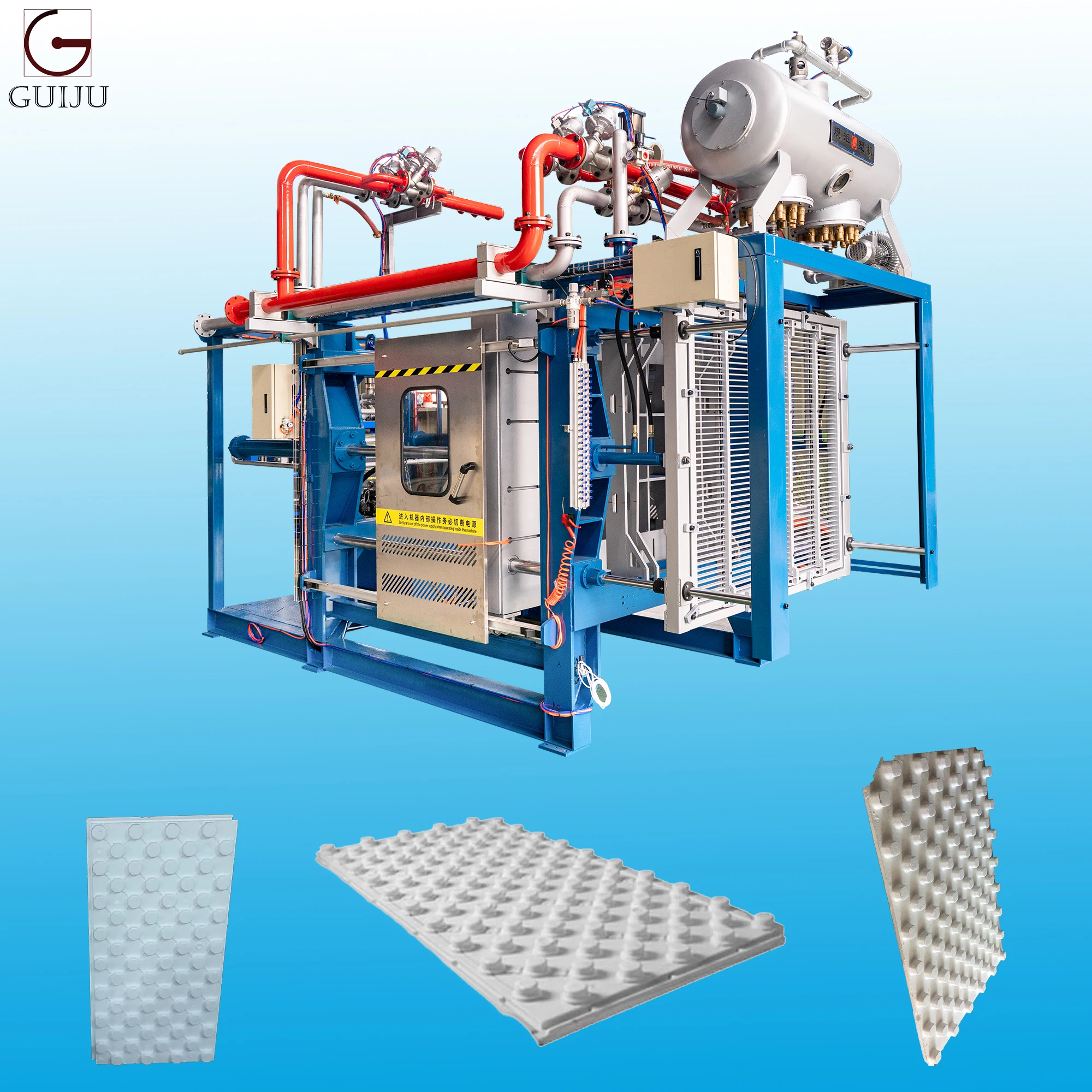

China Expanded Polystyrene EPS Machine EPS Block Molding Machine New EPS Foam Wall Panel Foam Board Production Line

- Overview

- Recommended Products

Guiju

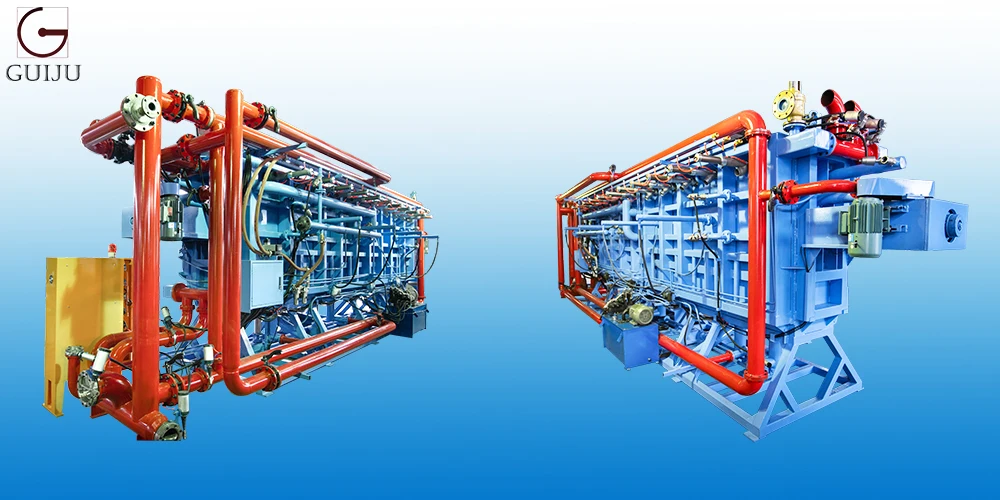

Introducing the China Expanded Polystyrene EPS Machine, a top-of-the-line EPS Block Molding Machine designed to revolutionize foam wall panel and foam board production. This cutting-edge machine is perfect for businesses looking to streamline their manufacturing process and produce high-quality EPS products efficiently.

The Guiju EPS Machine is known for its durability and precision, making it a reliable investment for any production line. The machine is equipped with advanced technology that allows for seamless block molding, creating EPS blocks that are uniform in size and quality. This guiju ensures that the final foam wall panels and foam boards are consistent and free from defects, meeting the highest industry standards.

One of the key features of the Guiju EPS Machine is its user-friendly interface, which makes it easy to operate and adjust settings based on specific production requirements. This allows for greater flexibility and customization, giving businesses the ability to produce a wide range of EPS products with ease.

Additionally, the Guiju EPS Machine is designed to maximize efficiency and reduce production time. With its fast processing speed and high capacity, this machine can significantly increase output without compromising on quality. This means businesses can meet demand quickly and efficiently, saving time and resources in the process.

Furthermore, the Guiju EPS Machine is built with sustainability in mind. It utilizes eco-friendly materials and energy-efficient technology to minimize environmental impact. By investing in this machine, businesses can reduce waste and promote a more sustainable manufacturing process.

the Guiju China Expanded Polystyrene EPS Machine is a game-changer for foam wall panel and foam board production. With its innovative design, user-friendly interface, and eco-friendly features, this machine is the perfect solution for businesses looking to enhance their EPS production capabilities. Don't miss out on this opportunity to take your manufacturing to the next level with the Guiju EPS Machine.

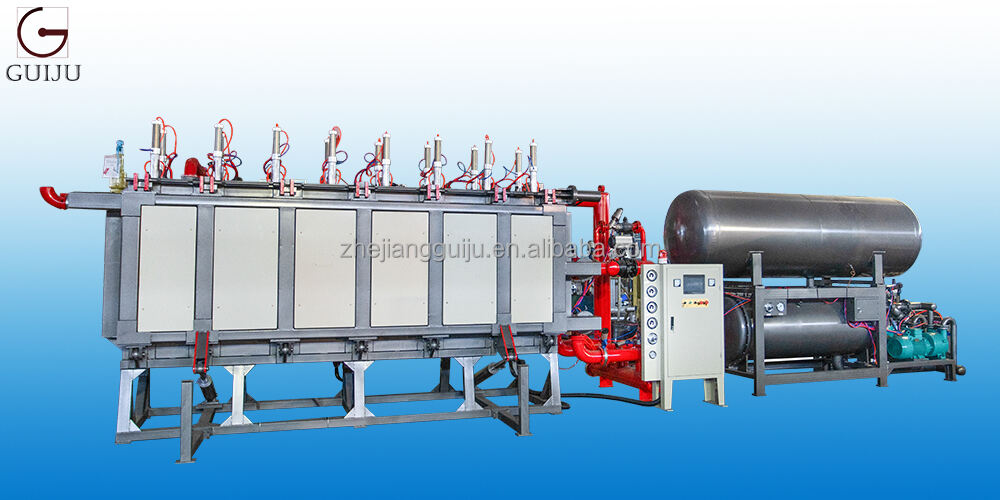

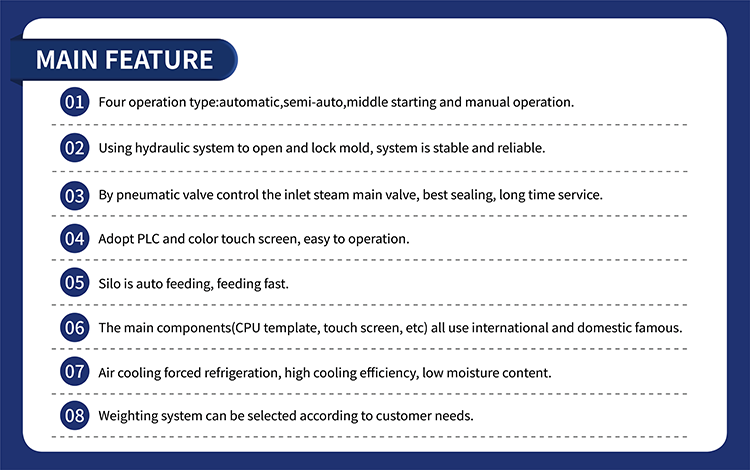

Automatic EPS block molding machine with vacuum cooling

model |

unit |

GJ-BZ-2000 |

GJ-BZ-3000 |

GJ-BZ-4000 |

GJ-BZ-6000 |

|||

mould Cavity Size |

mm |

2040*1240*1040 |

3050*1240*1040 |

4070*1240*1040 |

6090*1240*1040 |

|||

foam block size |

mm |

2000*1200*1000 |

3000*1200*1000 |

4000*1200*1000 |

6000*1200*1000 |

|||

steam system

|

inlet size |

mm |

DN100 |

DN100 |

DN150 |

DN150 |

||

inlet pressure |

bar |

5---8 |

5---8 |

5---8 |

5---8 |

|||

consumption |

kg/cycle |

30-50 |

40-70 |

55-85 |

70-130 |

|||

compressed air system

|

inlet size |

mm |

DN50 |

DN50 |

DN65 |

DN65 |

||

inlet pressure |

bar |

5-8 |

5-8 |

5-8 |

5-8 |

|||

consumption |

m³/cycle |

1-1.5 |

1.5-1.8 |

1.8-2 |

2-2.3 |

|||

injector sizeInjector

|

injector NO. |

8pcs |

10pcs |

16pcs |

22pcs |

|||

injector size |

DN80 |

DN80 |

DN80 |

DN80 |

||||

drainage pipe |

mm |

DN125 |

DN125 |

DN150 |

DN150 |

|||

vacuum drainage |

mm |

DN80 |

DN100 |

DN125 |

DN125 |

|||

condensation drainage |

mm |

DN100 |

DN125 |

DN125 |

DN125 |

|||

cycle Time (15g/l) |

min/cycle |

3 |

4 |

5 |

6 |

|||

vacuum pump power |

kw |

5.5kw*2 |

5.5kw*2 |

11kw*2 |

11kw*2 |

|||

installed Power |

kw |

20.5 |

22 |

33 |

33 |

|||

overall Size |

mm |

7500*3200*3500 |

5500*3200*3500 |

11000*3200*3500 |

13000*3200*3500 |

|||

machine weight |

kg |

6000 |

8000 |

10000 |

12000 |

|||