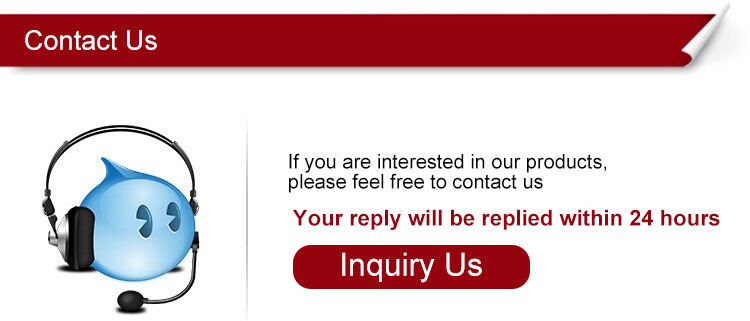

Factory Outlet Automatic Expanded Polystyrene Foam Beads Expander Machine EPS Pre-expender Machine

- Overview

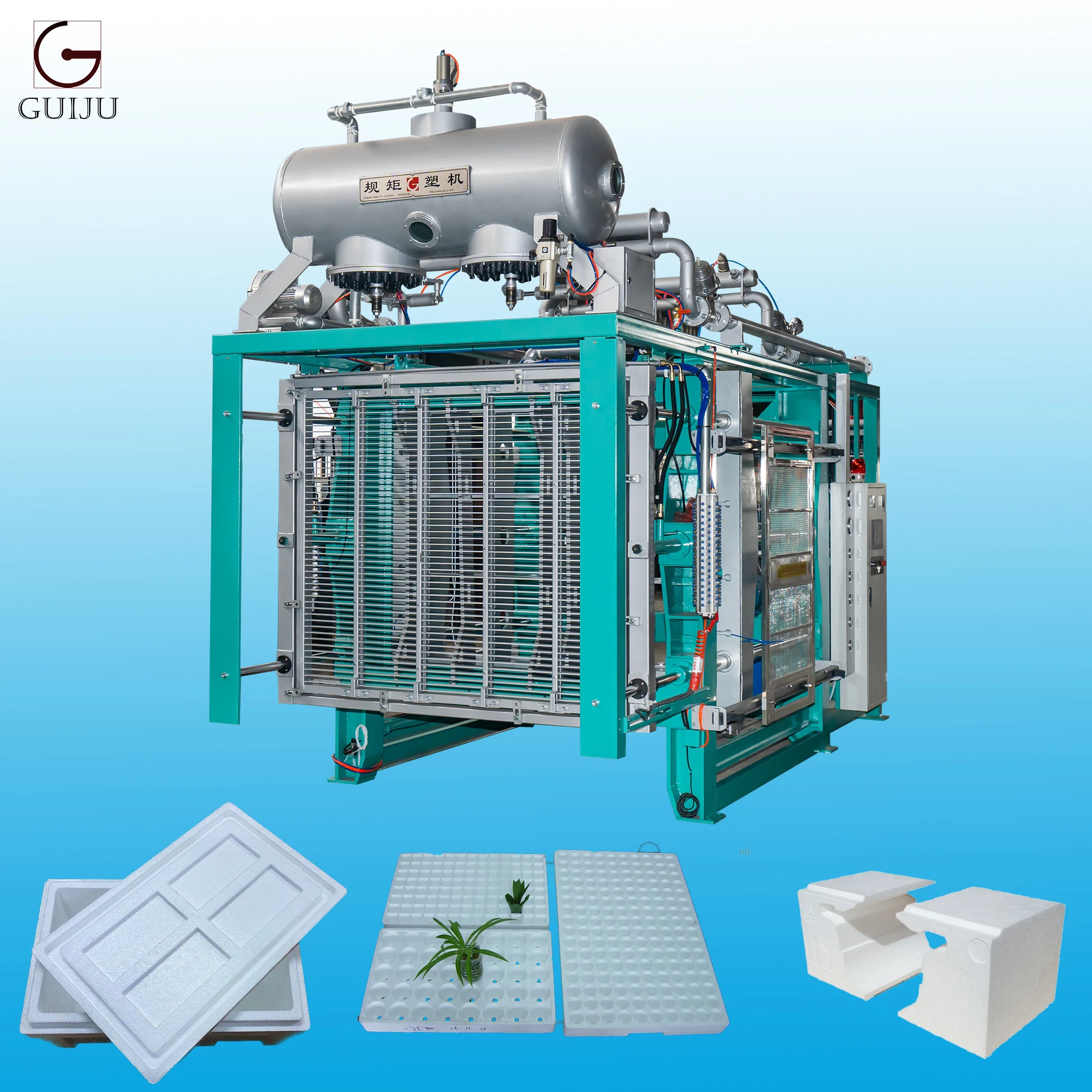

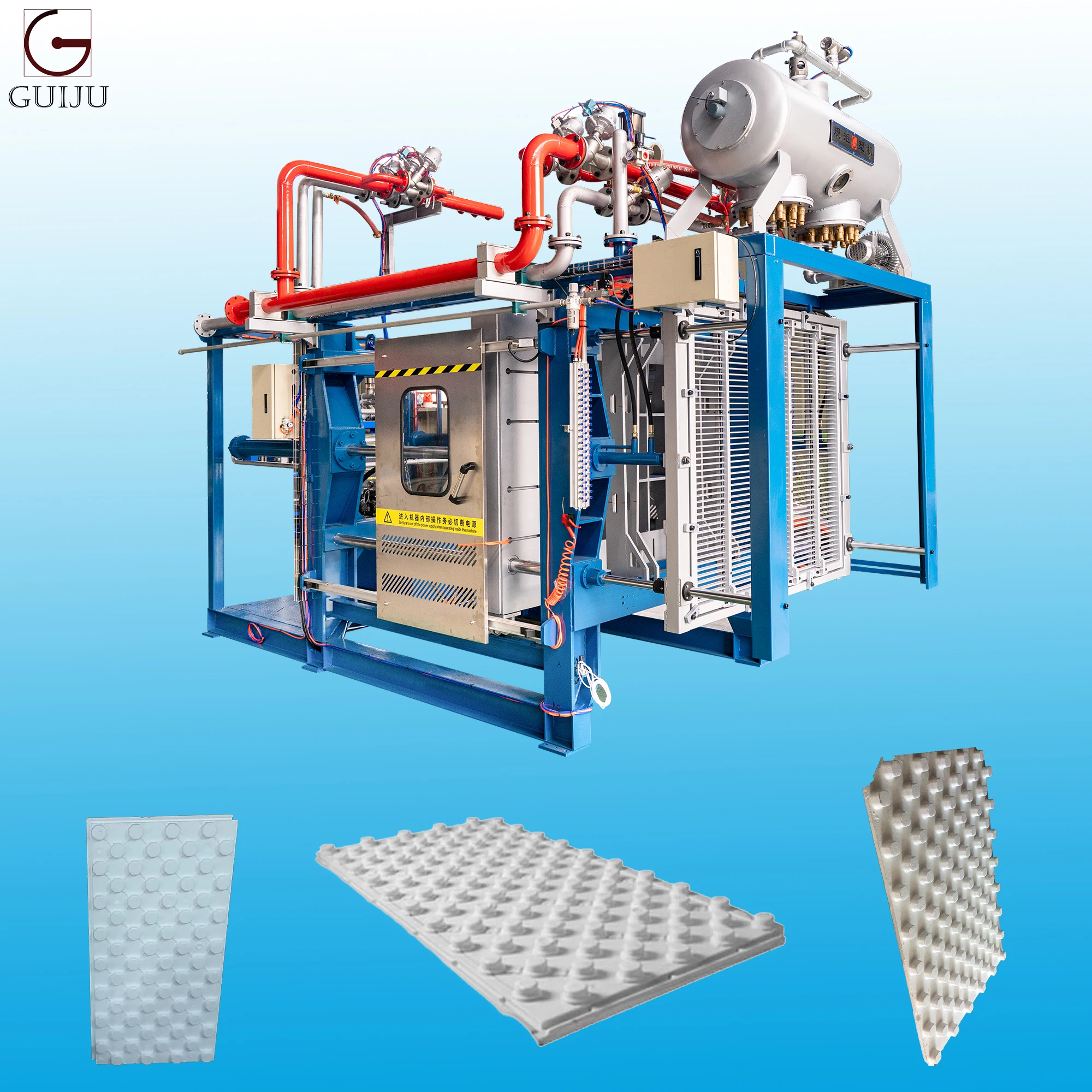

- Recommended Products

Automatic eps batch pre-expander machine

Main feature:

1. The machine controlled by PLC and color touch screen, realizes auto material suction, auto weighing, auto control barrel pressure and temperature, auto discharge, make sure auto production cycle; 2. The machine includes: main expansion body, dryer bed and weighing system. 3. The electrical appliances, pneumatic components and valves are well-known brands, which ensures machine working stability, reliability and long service life. 4. By German steam and air proportional valve control the chamber pressure and temperature, and by Korean vibration level sensor control the material level, make sure expanded eps beads full and consistent. (optional)

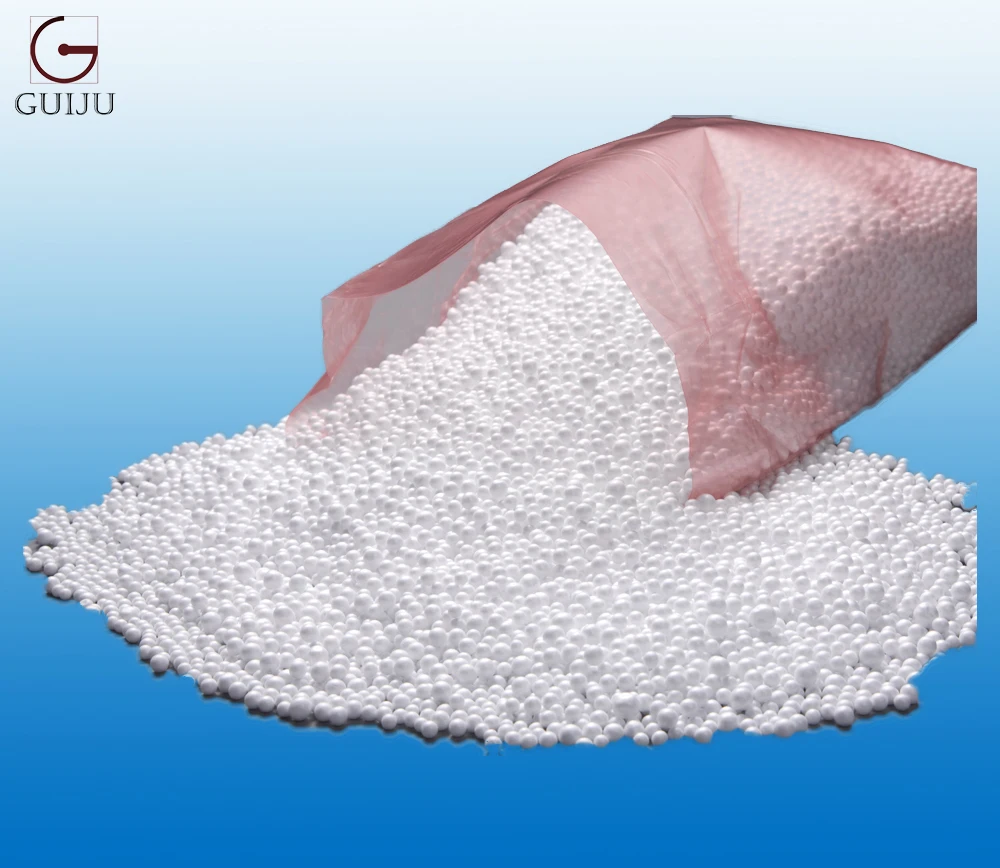

Technical data:

|

Model

|

unit

|

GJ-FJ-1100

|

GJ-FJ-1500

|

||

|

Chamber size

|

mm

|

Φ1100*1500

|

Φ1500*2200

|

||

|

Volume

|

m³

|

1.4

|

3.8

|

||

|

Expansion Rate

|

kg/m³

|

10-30

|

4-30

|

||

|

Density Tolerance

|

≤±3%

|

≤±5%

|

|||

|

Throughput

|

4g/l

|

Kg/H

|

--

|

180

|

|

|

10g/l

|

Kg/H

|

200

|

400

|

||

|

12g/l

|

Kg/H

|

240

|

600

|

||

|

15g/l

|

Kg/H

|

320

|

900

|

||

|

Steam system

|

Inlet

|

mm

|

DN50

|

DN50

|

|

|

Working pressure

|

bar

|

3---8

|

3---8

|

||

|

Compressed air

|

Inlet

|

mm

|

DN40

|

DN50

|

|

|

Working pressure

|

bar

|

6---8

|

6---8

|

||

|

Drain outlet

|

Drain outlet

|

mm

|

DN80

|

DN100

|

|

|

Fan Outlet

|

mm

|

Φ80

|

DN100

|

||

|

Energy consumption

|

Steam consumption

|

kg/cycle

|

8---11

|

13---16

|

|

|

Air consumption

|

m³/cycle

|

0.5---0.6

|

0.5---0.6

|

||

|

Installed power

|

kw

|

18

|

33

|

||

|

Overall Dimension

|

mm

|

6800*3200*4600

|

7400*4400*5400

|

||

|

Machine weight

|

kg

|

3500

|

4500

|

||