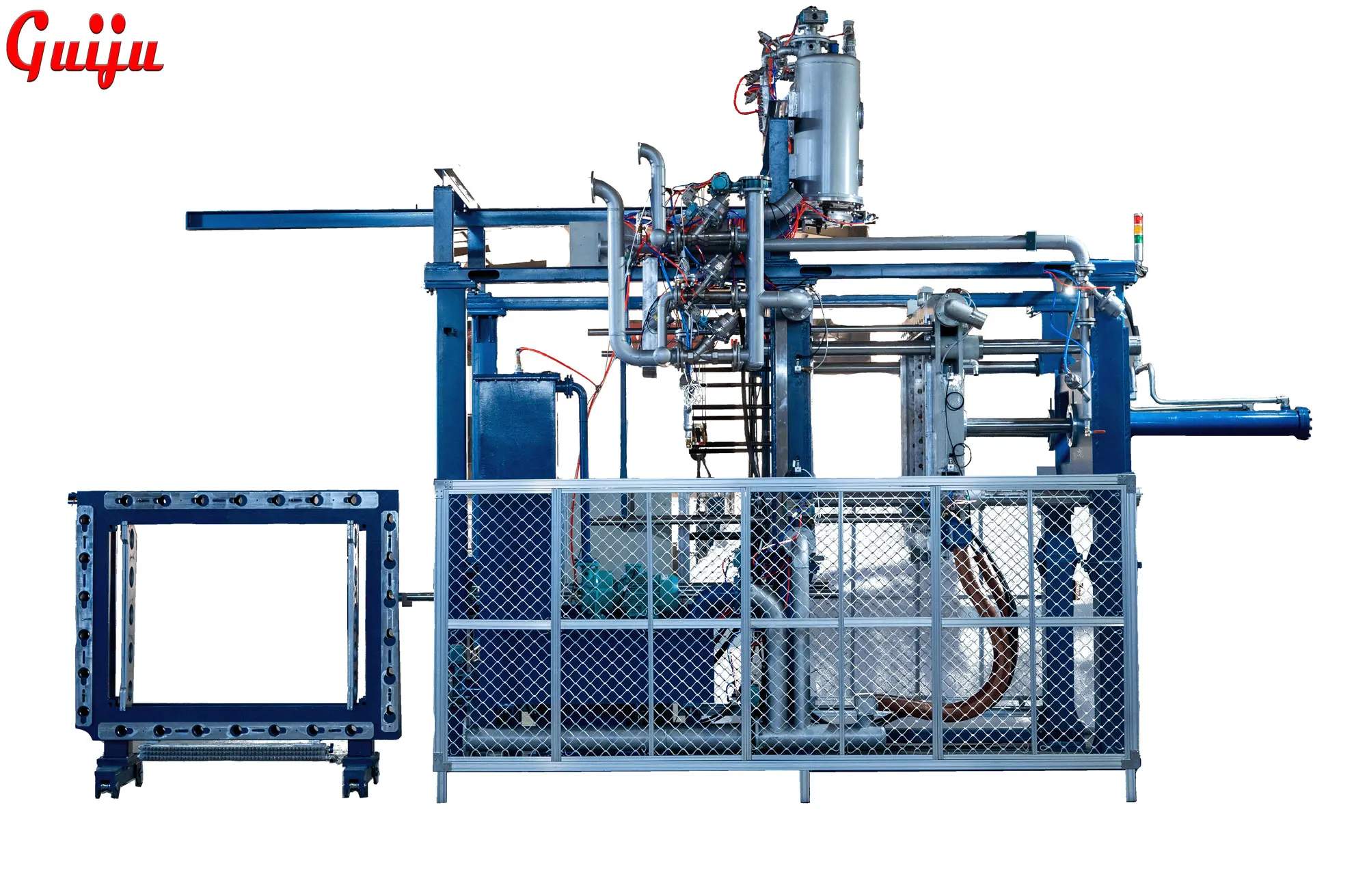

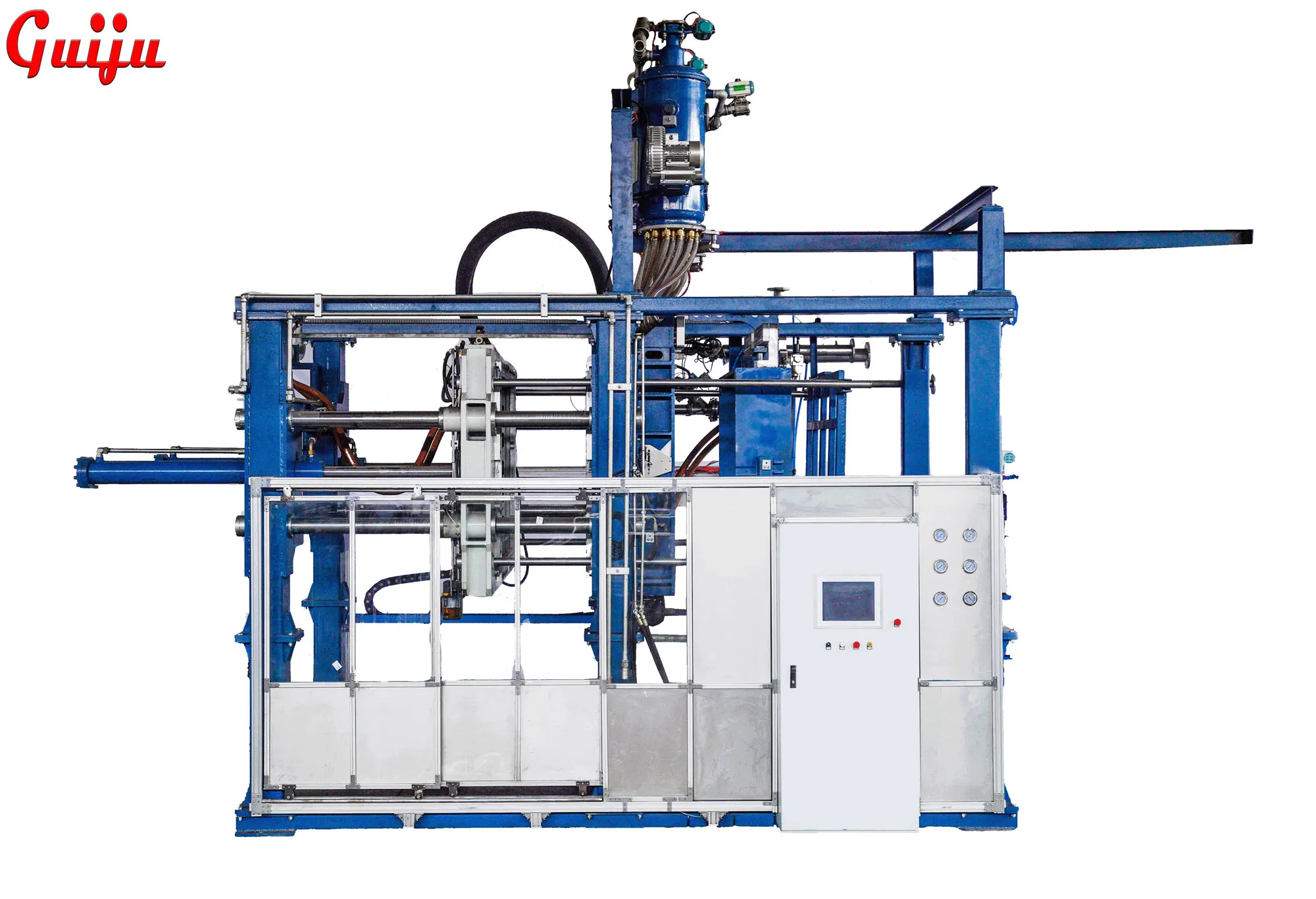

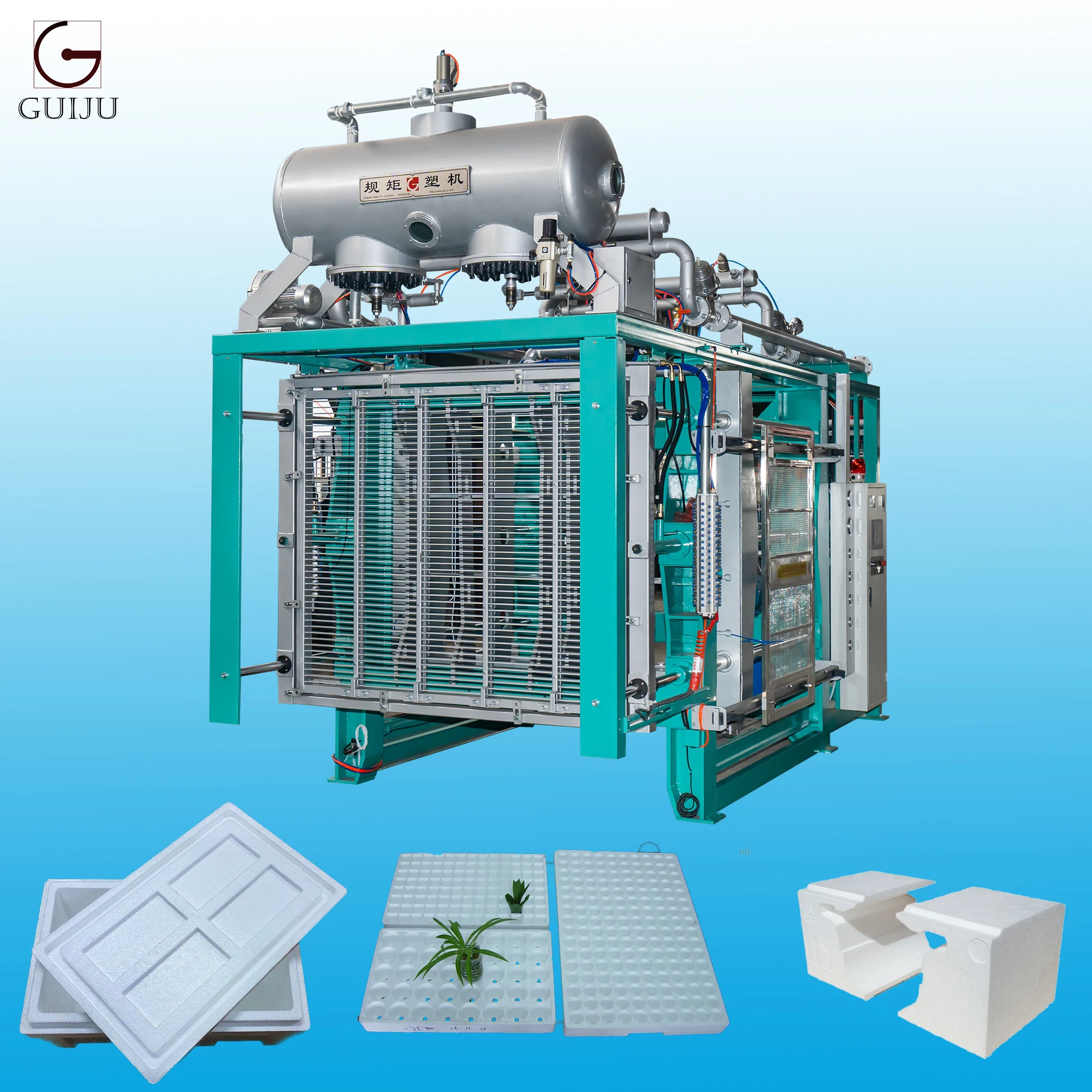

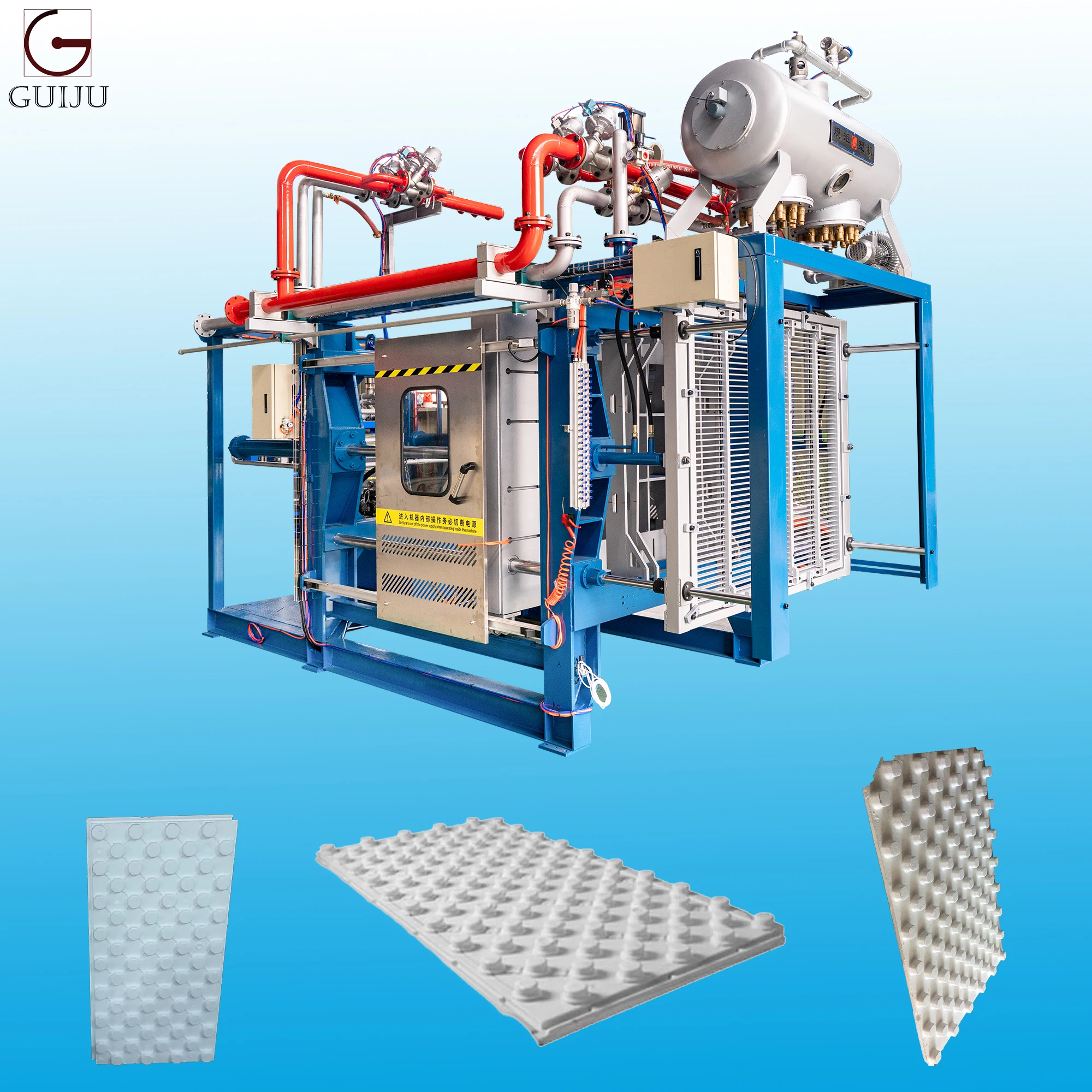

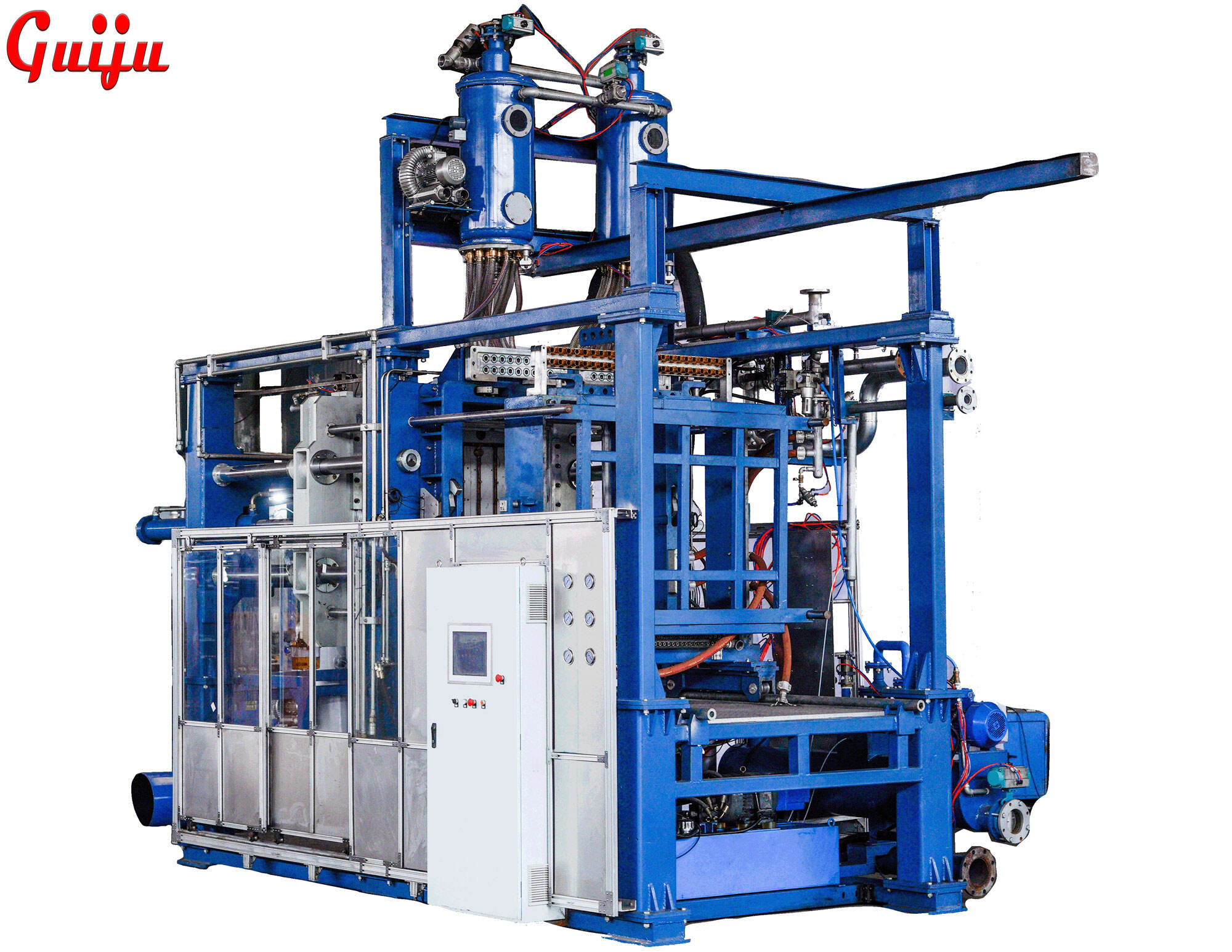

GUIJU Factory Direct Sales Fast Change Mold Type Auto EPS Foam Shape Molding Moulding Machine

- Overview

- Recommended Products

GUIJU

Introducing the Factory Direct Sales Fast Change Mold Type Auto EPS Foam Shape Molding Moulding Machine, the latest innovation in foam shaping technology. This cutting-edge machine, proudly brought to you by the trusted brand GUIJU, is designed for efficiency, precision, and convenience.

With this advanced moulding machine, you can quickly and easily create custom foam shapes with a simple and fast change of mold types. The intuitive GUIJU Factory Direct Sales Fast Change Mold Type Auto EPS Foam Shape Molding Moulding Machine is perfect for businesses looking to streamline their production process and increase productivity.

The machine is equipped with state-of-the-art technology that ensures high-quality foam shaping results every time. Whether you are producing foam packaging, insulation, or decorative shapes, this machine can handle it all with speed and accuracy. The GUIJU Factory Direct Sales Fast Change Mold Type Auto guiju EPS Foam Shape Molding Moulding Machine is ideal for a wide range of industries, including packaging, construction, and manufacturing.

One of the key features of this machine is its fast mold change capability. With just a few simple steps, you can switch between different mold types to create a variety of foam shapes without any downtime. This flexibility allows you to meet the changing demands of your customers and stay ahead of the competition.

In addition to its fast mold change feature, the GUIJU Factory Direct Sales Fast Change Mold Type Auto EPS Foam Shape Molding Moulding Machine is also easy to operate and maintain. Its user-friendly interface makes it simple to adjust settings and monitor the production process. The machine is built to last, with durable components that ensure reliable performance over time.

Invest in the GUIJU Factory Direct Sales Fast Change Mold Type Auto EPS Foam Shape Molding Moulding Machine and take your foam shaping capabilities to the next level. With its innovative design, advanced technology, and reliable performance, this machine is a must-have for any business looking to optimize their foam production process. Experience the difference with GUIJU – your trusted partner for high-quality foam shaping solutions.

Top sales fast change mold automatic eps shape molding machine with vecuum cooling

Main feature:

Technical data

Subjects |

Unit |

GJ-ZQE-0907 |

GJ-ZQE-1210 |

GJ-ZQE-1412 |

GJ-ZQE-1614 |

|||||

Max. Product size |

mm |

720×520 |

1120×920 |

1320×1120 |

1520×1320 |

|||||

Max. thickness size |

mm |

350 |

350 |

350 |

350 |

|||||

Moving mold max. speed |

mm/s |

200 |

200 |

200 |

200 |

|||||

Hopper

|

Volume |

L |

125 |

125 |

250 |

250 |

||||

outlet QTY |

PC |

22 |

22 |

44 |

44 |

|||||

steam system

|

Inlet size |

inch |

DN80 |

DN80 |

DN80 |

DN100 |

||||

Mould inlet |

/ |

machine comes with |

||||||||

steam

|

working pressure |

Bar |

2~4 |

2~4 |

2~4 |

2~4 |

||||

Consumption |

Kg/Cycle |

1.8---3.5 |

2.5---4.5 |

4---5.5 |

5.5---8 |

|||||

air system--low pressure

|

Inlet size |

mm |

DN50 |

DN50 |

DN65 |

DN80 |

||||

Inlet pressure |

bar |

4~5 |

4~5 |

4~5 |

4~5 |

|||||

Consumption |

m3/Cycle |

0.5---1 |

0.5---1 |

1---1.5 |

1---1.5 |

|||||

air system--high pressure |

Inlet size |

mm |

DN25 |

DN25 |

DN25 |

DN25 |

||||

Inlet pressure |

bar |

5---7 |

5---7 |

5---7 |

5---7 |

|||||

Consumption |

m3/Cycle |

0.2 |

0.3 |

0.4 |

0.4 |

|||||

cooling water

system

|

Inlet size |

inch |

DN65 |

DN80 |

DN80 |

DN80 |

||||

Mould inlet |

mm |

Ø32*2 |

Ø32*2 |

Ø32*2 |

Ø32*3 |

|||||

Inlet pressure |

bar |

4---5 |

4---5 |

4---5 |

4---5 |

|||||

Consumption |

L/Cycle |

13~40 |

13~50 |

13~50 |

13~63 |

|||||

Temperature |

℃ |

45~60 |

45~60 |

45~60 |

45~60 |

|||||

Vacuum System |

vacuum inlet |

mm |

DN100 |

DN100 |

DN100 |

DN125 |

||||

vacuum tank sewage |

mm |

DN65 |

DN65 |

DN80 |

DN80 |

|||||

cooling water consumption |

L |

50 |

50 |

50 |

50 |

|||||

Drainage system |

pipe diameter |

mm |

DN125 |

DN125 |

DN150 |

DN150 |

||||

Oil pump |

pressure |

bar |

100---150 |

100---150 |

100---150 |

100---150 |

||||

Cycle Time |

S/Cycle |

45~75 |

50~90 |

55~100 |

60~110 |

|||||

Installation power |

kw |

11 |

12.5 |

12.5 |

16.5 |

|||||

Motor |

hydraulic |

kw |

5.5 |

5.5 |

7.5 |

7.5 |

||||

feeding |

kw |

1.5 |

1.5 |

2.2 |

2.2 |

|||||