Guiju High Capacity CE Certified EPS Polystyrene Beads Pre-Expaner Machine Easy to Operate For Styrofoam Beads Making

- Overview

- Recommended Products

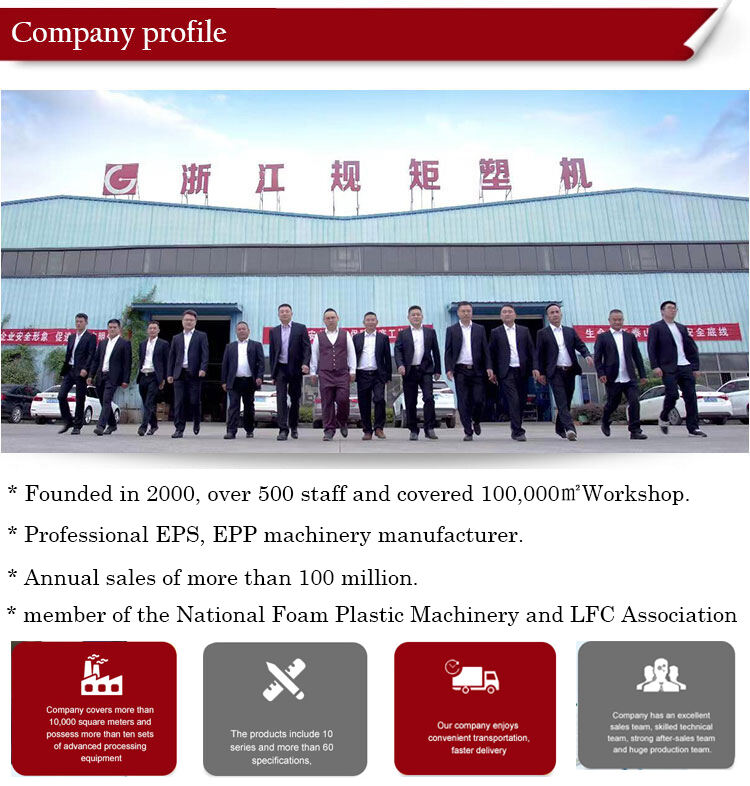

Guiju

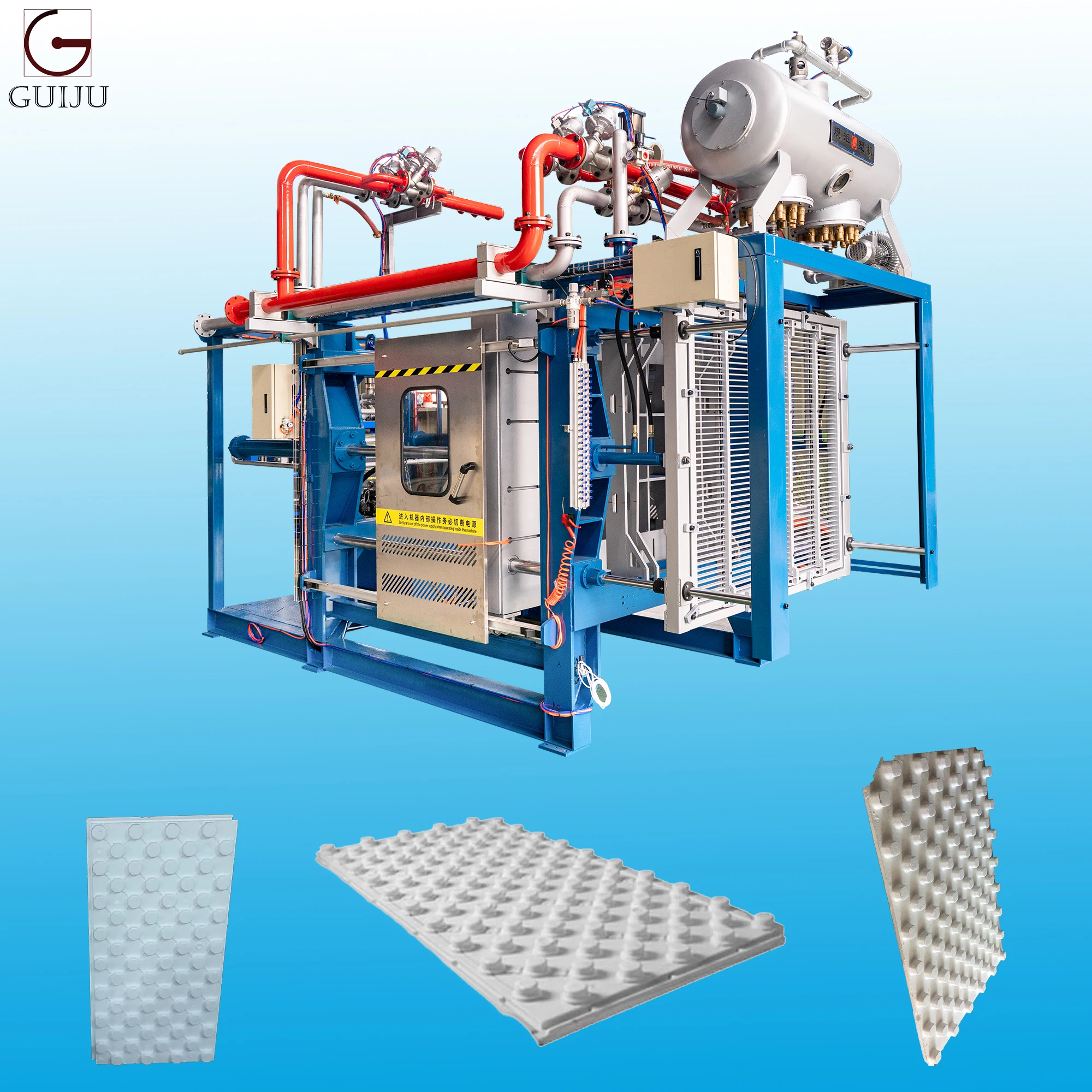

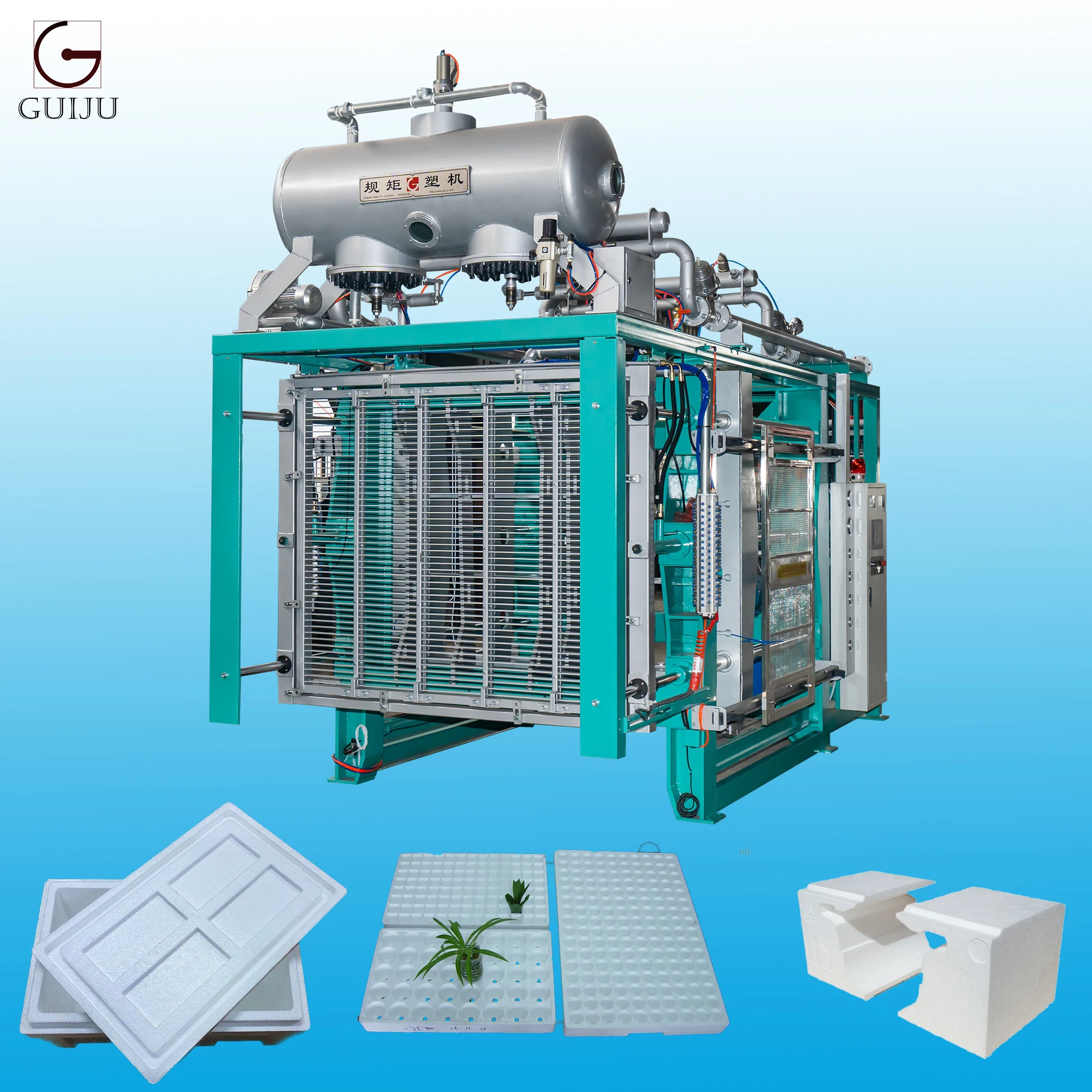

Introducing the High Capacity EPS Polystyrene Beads Pre-Expander Machine, the latest innovation in Styrofoam bead making technology. This top-of-the-line machine is designed to make the process of pre-expanding EPS beads quick, easy, and efficient.

With a CE certification, you can trust that this machine meets high safety and quality standards. The Guiju pre-expander machine is built to last, with a durable construction that ensures years of reliable use.

One of the standout features of this machine is its high capacity design, allowing you to pre-expand large quantities of EPS beads in a single operation. This means you can increase your production output and meet demand more effectively.

The Guiju pre-expander machine is also incredibly easy to operate, making it a great choice for both experienced professionals and those new to the industry. The intuitive controls and clear display make it simple to adjust settings and monitor the pre-expanding process.

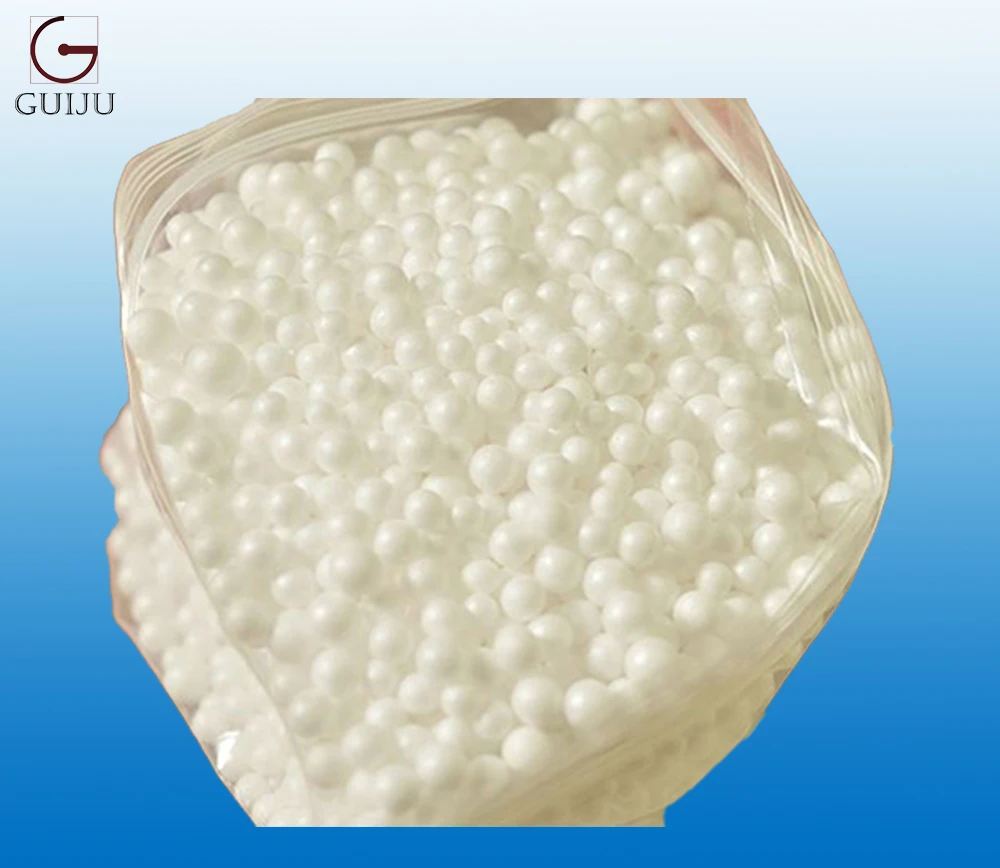

Thanks to its advanced technology, this machine produces uniform and high-quality pre-expanded EPS beads that are ideal for a variety of applications. Whether you are making packaging materials, crafting decorative items, or creating insulation products, the Guiju pre-expander machine ensures consistent results every time.

When it comes to Styrofoam bead making, the Guiju High Capacity EPS Polystyrene Beads Pre-Expander Machine is the perfect choice. Trust in the Guiju brand for a top-quality, reliable machine that will streamline your production process and help you achieve outstanding results. Order yours today and experience the difference that the Guiju pre-expander machine can make for your business.

Automatic eps batch pre-expander machine

Main feature:

Technical data:

Model |

unit |

GJ-FJ-1100 |

GJ-FJ-1500 |

||

Chamber size |

mm |

Φ1100*1500 |

Φ1500*2200 |

||

Volume |

m³ |

1.4 |

3.8 |

||

Expansion Rate |

kg/m³ |

10-30 |

4-30 |

||

Density Tolerance |

≤±3% |

≤±5% |

|||

Throughput

|

4g/l |

Kg/H |

-- |

180 |

|

10g/l |

Kg/H |

200 |

400 |

||

12g/l |

Kg/H |

240 |

600 |

||

15g/l |

Kg/H |

320 |

900 |

||

Steam system

|

Inlet |

mm |

DN50 |

DN50 |

|

Working pressure |

bar |

3---8 |

3---8 |

||

Compressed air

|

Inlet |

mm |

DN40 |

DN50 |

|

Working pressure |

bar |

6---8 |

6---8 |

||

Drain outlet

|

Drain outlet |

mm |

DN80 |

DN100 |

|

Fan Outlet |

mm |

Φ80 |

DN100 |

||

Energy consumption

|

Steam consumption |

kg/cycle |

8---11 |

13---16 |

|

Air consumption |

m³/cycle |

0.5---0.6 |

0.5---0.6 |

||

Installed power |

kw |

18 |

33 |

||

Overall Dimension |

mm |

6800*3200*4600 |

7400*4400*5400 |

||

Machine weight |

kg |

3500 |

4500 |

||