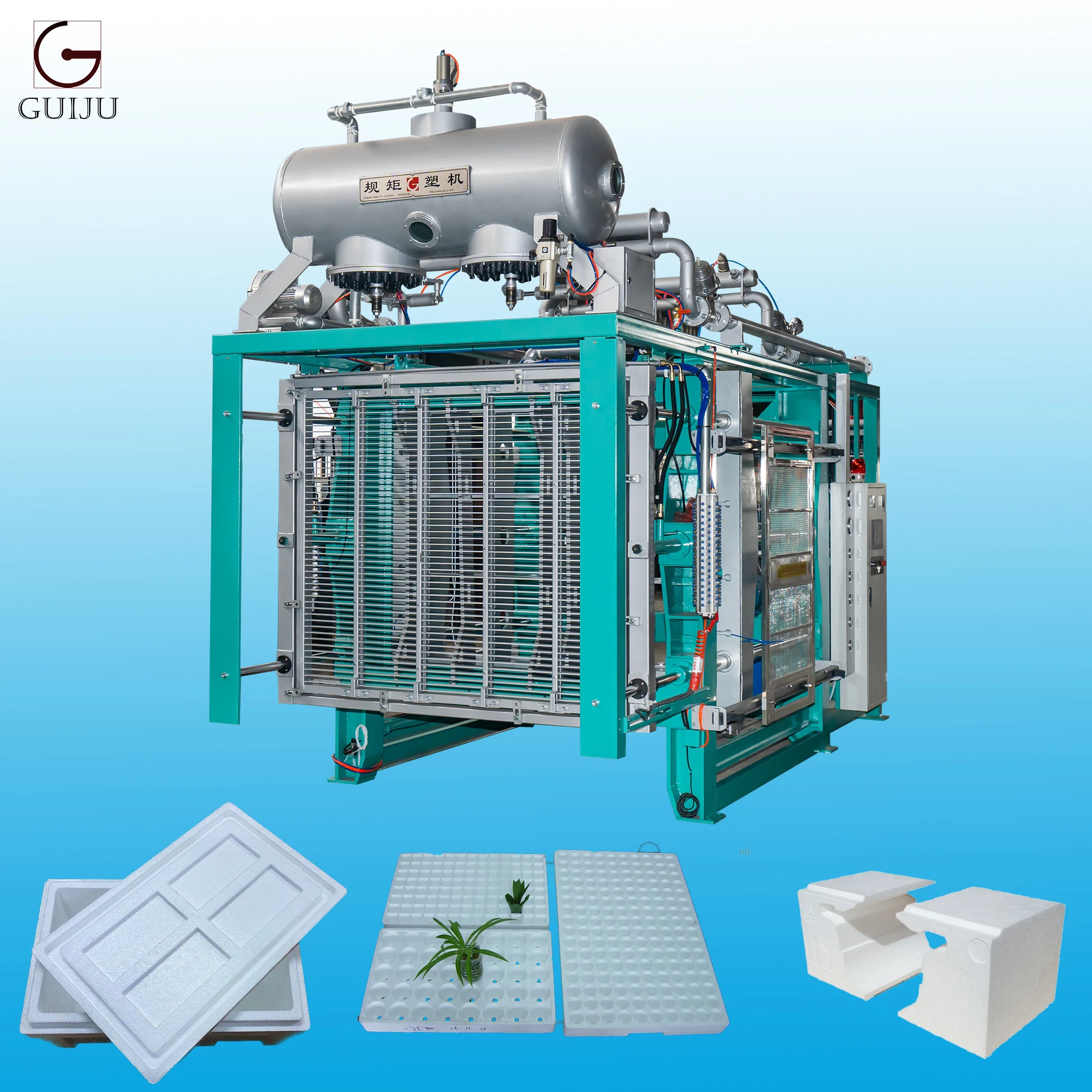

High Efficiency Automatic EPS Shape Moulding Machine Energy-Saving ICF Block Building Foam Machinery for Manufacturing Plant

- Overview

- Recommended Products

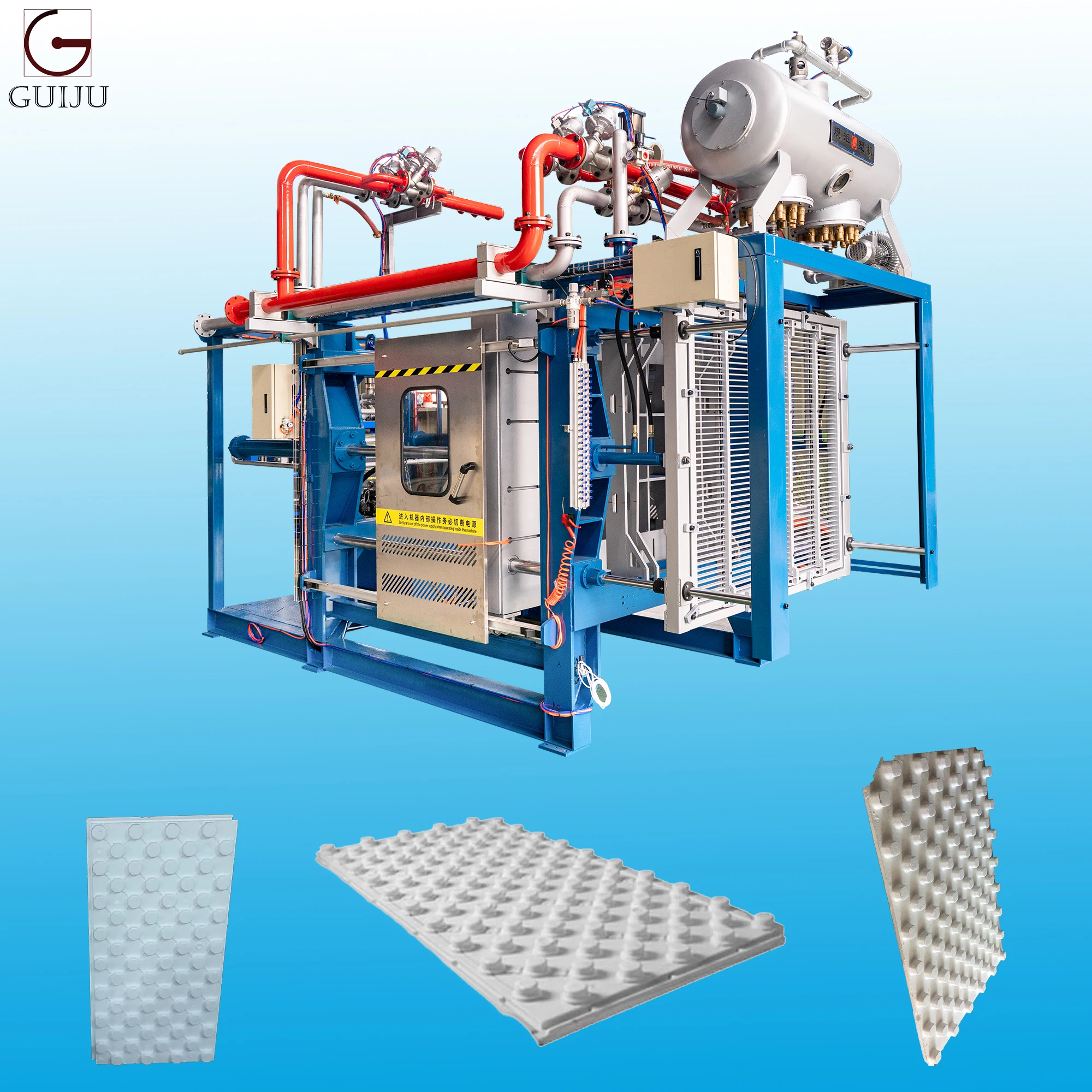

Introducing, the High Efficiency Automatic EPS Shape Moulding Machine from Guiju, a cutting-edge piece of foam machinery designed for manufacturing plants looking to streamline their production process. This innovative machine is perfect for creating ICF block building foam, making it an essential tool for construction companies and manufacturers.

What sets the Guiju’s EPS Shape Moulding Machine apart is its high efficiency and automatic features. With a fully automated system, this machine can produce EPS shapes quickly and accurately, saving time and labor costs. The high efficiency of this machine ensures that production runs smoothly and efficiently, increasing output and reducing downtime.

Additionally, the Guiju’s EPS Shape Moulding Machine is energy-saving, making it an environmentally friendly choice for manufacturing plants. By using advanced technology and energy-efficient components, this machine consumes less electricity and reduces overall energy consumption. This not only saves money on utility bills but also helps to lower carbon emissions and promote sustainability.

The ICF block building foam produced by the Guiju’s EPS Shape Moulding Machine is of the highest quality, with precise shapes and dimensions. This foam is lightweight yet durable, making it an ideal material for construction projects. Whether you are building walls, floors, or roofs, ICF block building foam made by this machine is sure to meet all your construction needs.

The Guiju’s EPS Shape Moulding Machine is easy to operate and maintain, with user-friendly controls and a durable construction that ensures long-lasting performance. This machine is designed for maximum productivity and reliability, so you can trust it to deliver consistent results time and time again.

The High Efficiency Automatic EPS Shape Moulding Machine from Guiju is a top-of-the-line foam machinery that is perfect for manufacturing plants looking to improve their production process. With its energy-saving features, high efficiency, and automatic capabilities, this machine is sure to streamline your operations and boost your bottom line. Invest in the Guiju’s EPS Shape Moulding Machine today and take your manufacturing plant to the next level

Top sales automatic eps shape molding machine with vacuum cooling

Main feature:

Technical data

Subjects |

Unit |

GJ-ZK-1210 |

GJ-ZK-1412 |

GJ-ZK-1513 |

GJ-ZK-17150 |

GJ-ZK-1816 |

||||||

Standard mould size |

mm |

1200×1000 |

1400×1200 |

1500×1300 |

1750×1550 |

1850×1600 |

||||||

Rear Window size |

mm |

1100×900 |

1250×1120 |

1350×1150 |

1600×1400 |

1700×1450 |

||||||

Max. Product size |

mm |

1030×830 |

1230×1030 |

1330×1130 |

1580×1380 |

1680×1430 |

||||||

Max. thickness size |

mm |

400 |

400 |

400 |

400 |

400 |

||||||

steam system

|

Inlet size |

mm |

DN80 |

DN80 |

DN80 |

DN100 |

DN100 |

|||||

Mould inlet |

/ |

DN25 |

DN40 |

DN40 |

DN40 |

DN40 |

||||||

steam

|

Inlet pressure |

Bar |

3~6 |

3~6 |

3~6 |

3~6 |

3~6 |

|||||

Consumption |

Kg/Cycle |

raw material consumption per ton is about 10---12 tons |

||||||||||

Air system

|

Inlet size |

mm |

DN50 |

DN50 |

DN50 |

DN50 |

DN50 |

|||||

Inlet pressure |

bar |

4~5 |

4~5 |

4~5 |

4~5 |

4~5 |

||||||

Consumption |

m3/Cycle |

1.5 |

1.8 |

2 |

2 |

2.2 |

||||||

Cooling water

system

|

Inlet size |

mm |

DN80 |

DN80 |

DN80 |

DN80 |

DN80 |

|||||

Mould inlet |

mm |

DN25 |

DN25 |

DN25 |

DN25 |

DN25 |

||||||

Inlet pressure |

bar |

3~4 |

3~4 |

3~4 |

3~4 |

3~4 |

||||||

Consumption |

Kg/Cycle |

40~120 |

50~140 |

50~160 |

60~180 |

70~190 |

||||||

Temperature |

℃ |

40~50 |

40~50 |

40~50 |

40~50 |

40~50 |

||||||

Vacuum System |

Drainage outlet |

mm |

DN80 |

DN80 |

DN80 |

DN80 |

DN80 |

|||||

vacuum motor power |

kw |

4 |

5.5 |

5.5 |

7.5 |

7.5 |

||||||

vacuum pump capacity |

m³/h |

165 |

230 |

230 |

280 |

280 |

||||||

Drainage system |

Outlet size |

mm |

DN100 |

DN150 |

DN150 |

DN150 |

DN150 |

|||||

Cycle Time |

S/Cycle |

50~90 |

50~130 |

70~160 |

80~180 |

90~180 |

||||||

Installation power |

kw |

11 |

12.5 |

12.5 |

16.5 |

16.5 |

||||||

Oversize - L*W*H |

mm |

5200×2100×3700 |

5200×2300×3600 |

5200×2400×3800 |

5300×2700×4000 |

5300×2800×4100 |

||||||

Machine Weight |

Kg |

5300 |

5900 |

6100 |

7100 |

7400 |

||||||