High Efficiency Vacuum Cooling EPS Block Molding Moulding Machine CE Certified EPS Foam Wall Panel Sheet Production Line

- Overview

- Recommended Products

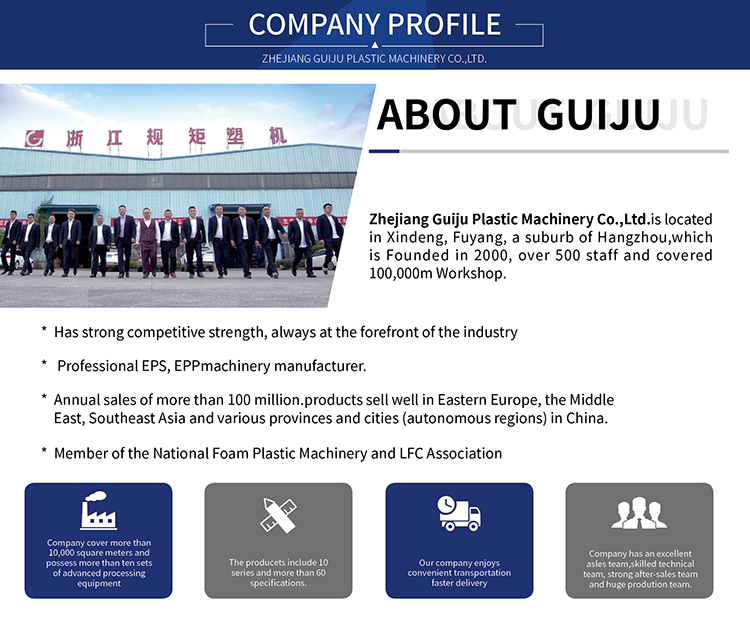

Guiju

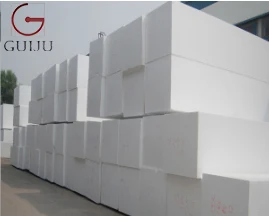

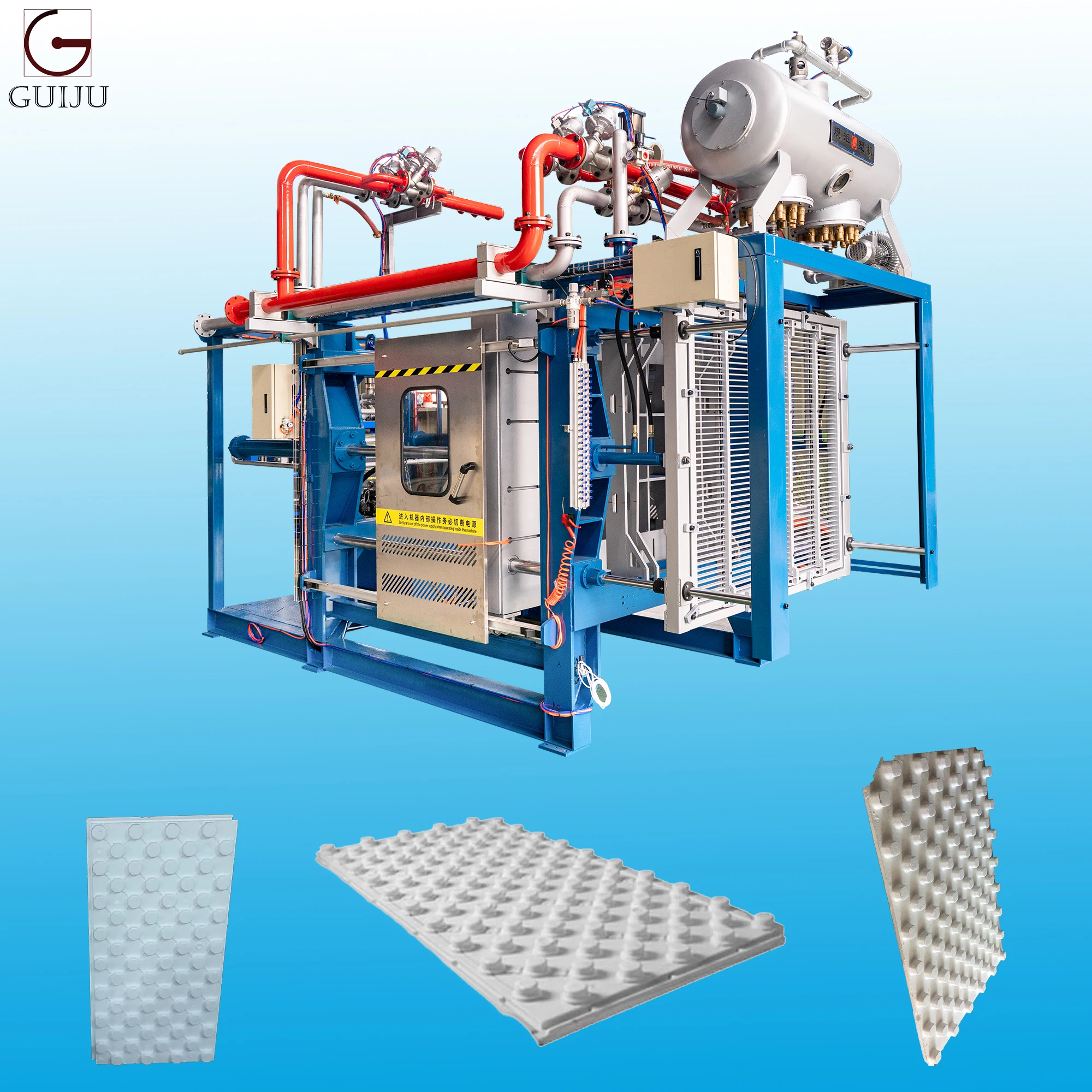

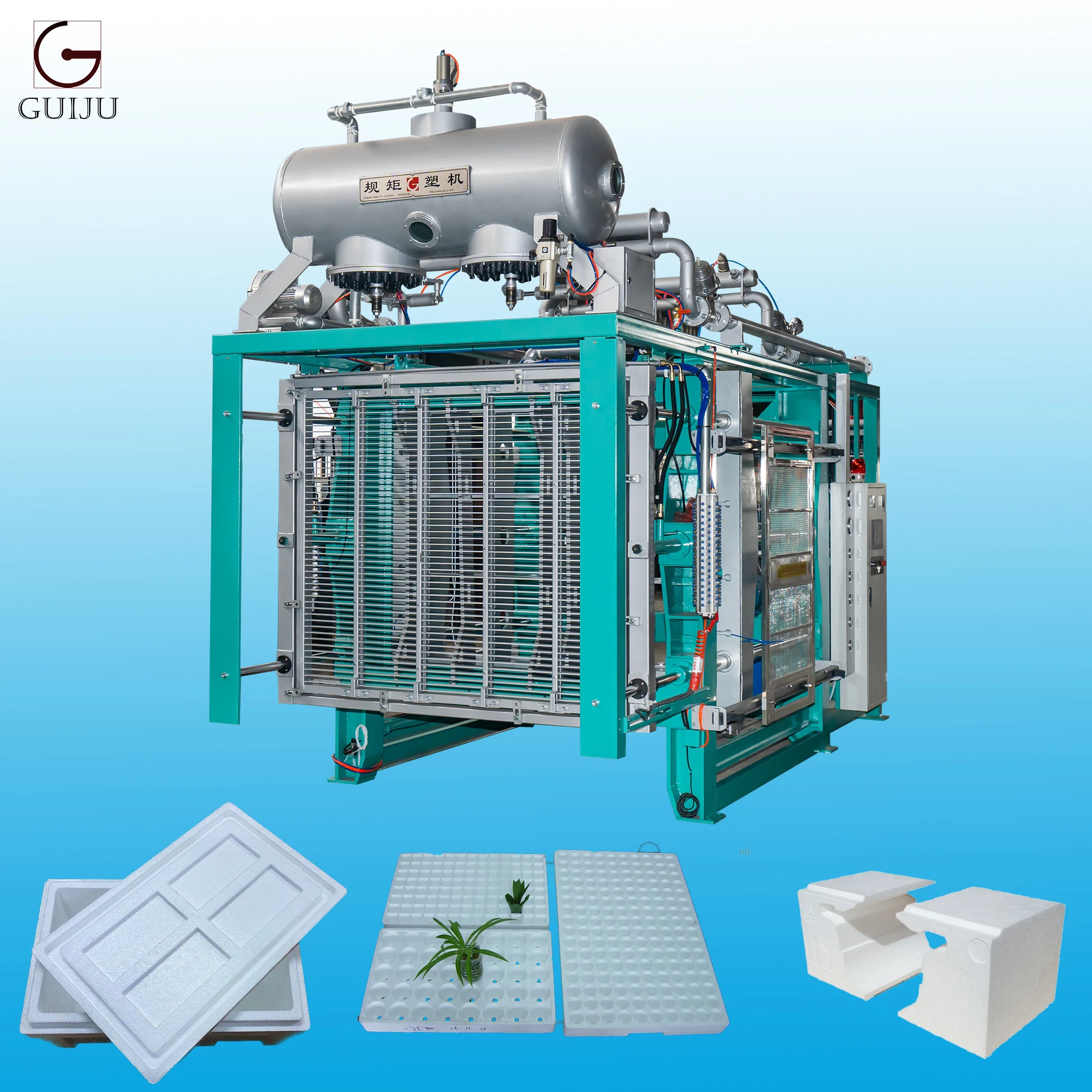

Introducing the High Efficiency Vacuum Cooling EPS Block Molding Machine, a top-of-the-line product that is perfect for creating EPS foam wall panels and sheets with precision and ease. This CE certified machine is ideal for businesses looking to streamline their production process and increase efficiency.

This state-of-the-art machine is designed to save you time and money while producing high-quality EPS foam products. The vacuum cooling system ensures that your blocks are formed quickly and accurately, resulting in a consistent and uniform finished product. With this machine, you can produce EPS foam wall panels and sheets in a fraction of the time it would take with traditional methods.

The Guiju High Efficiency Vacuum Cooling guiju EPS Block Molding Machine is easy to operate, with user-friendly controls that allow you to adjust settings and monitor progress with ease. The machine is also equipped with safety features to ensure a secure working environment for you and your employees.

With this production line, you can create EPS foam products that are durable, lightweight, and perfect for a variety of applications. Whether you are in the construction industry, packaging industry, or any other industry that requires EPS foam products, this machine is the perfect solution for your production needs.

The Guiju High Efficiency Vacuum Cooling EPS Block Molding Machine is built to last, with durable construction and quality materials that ensure long-lasting performance. This machine is designed to withstand the rigors of daily use and deliver reliable results time and time again.

If you are looking to upgrade your production process and increase efficiency, look no further than the Guiju High Efficiency Vacuum Cooling EPS Block Molding Machine. With its CE certification and reputation for quality, this machine is the perfect choice for businesses looking to take their production to the next level. Invest in this machine today and watch your production capabilities soar.

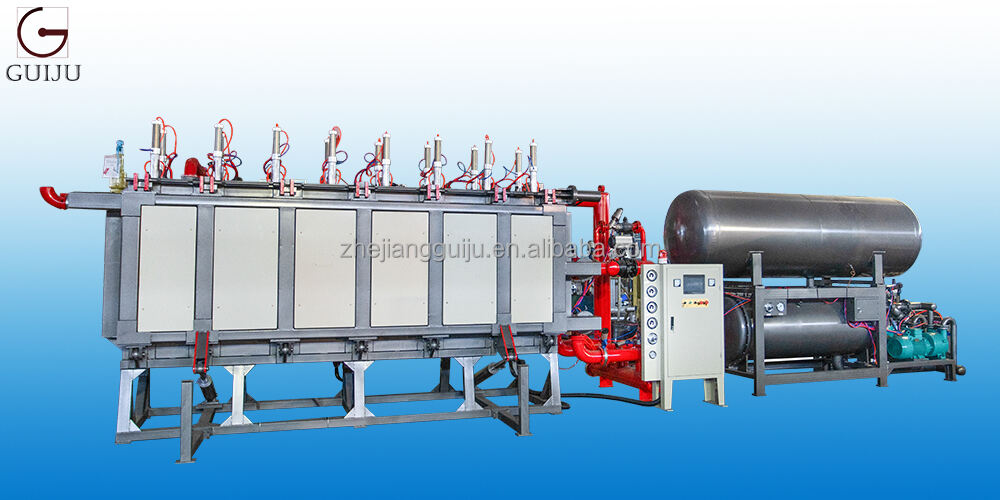

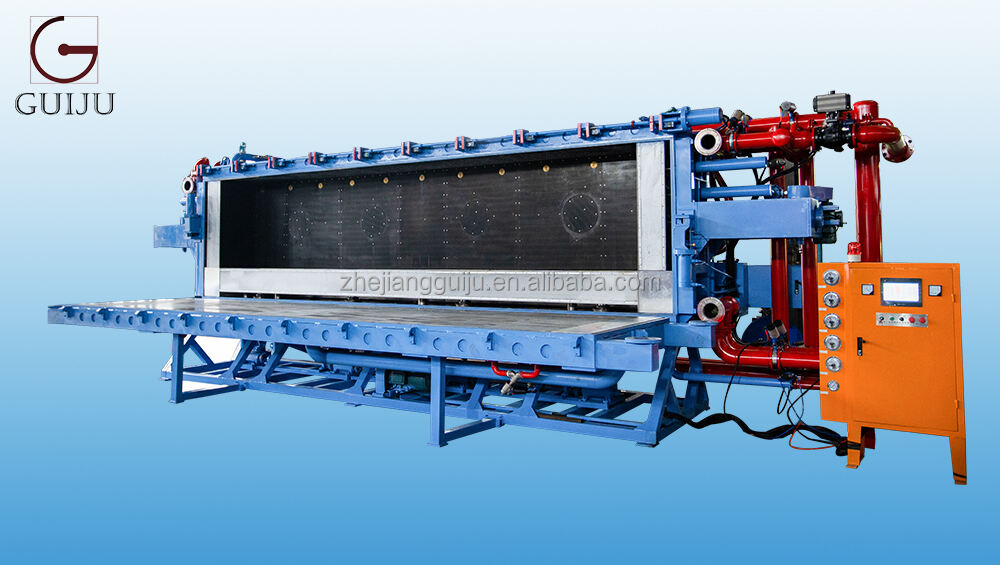

Automatic EPS block molding machine with vacuum cooling

model |

unit |

GJ-BZ-2000 |

GJ-BZ-3000 |

GJ-BZ-4000 |

GJ-BZ-6000 |

|||

mould Cavity Size |

mm |

2040*1240*1040 |

3050*1240*1040 |

4070*1240*1040 |

6090*1240*1040 |

|||

foam block size |

mm |

2000*1200*1000 |

3000*1200*1000 |

4000*1200*1000 |

6000*1200*1000 |

|||

steam system

|

inlet size |

mm |

DN100 |

DN100 |

DN150 |

DN150 |

||

inlet pressure |

bar |

5---8 |

5---8 |

5---8 |

5---8 |

|||

consumption |

kg/cycle |

30-50 |

40-70 |

55-85 |

70-130 |

|||

compressed air system

|

inlet size |

mm |

DN50 |

DN50 |

DN65 |

DN65 |

||

inlet pressure |

bar |

5-8 |

5-8 |

5-8 |

5-8 |

|||

consumption |

m³/cycle |

1-1.5 |

1.5-1.8 |

1.8-2 |

2-2.3 |

|||

injector sizeInjector

|

injector NO. |

8pcs |

10pcs |

16pcs |

22pcs |

|||

injector size |

DN80 |

DN80 |

DN80 |

DN80 |

||||

drainage pipe |

mm |

DN125 |

DN125 |

DN150 |

DN150 |

|||

vacuum drainage |

mm |

DN80 |

DN100 |

DN125 |

DN125 |

|||

condensation drainage |

mm |

DN100 |

DN125 |

DN125 |

DN125 |

|||

cycle Time (15g/l) |

min/cycle |

3 |

4 |

5 |

6 |

|||

vacuum pump power |

kw |

5.5kw*2 |

5.5kw*2 |

11kw*2 |

11kw*2 |

|||

installed Power |

kw |

20.5 |

22 |

33 |

33 |

|||

overall Size |

mm |

7500*3200*3500 |

5500*3200*3500 |

11000*3200*3500 |

13000*3200*3500 |

|||

machine weight |

kg |

6000 |

8000 |

10000 |

12000 |

|||