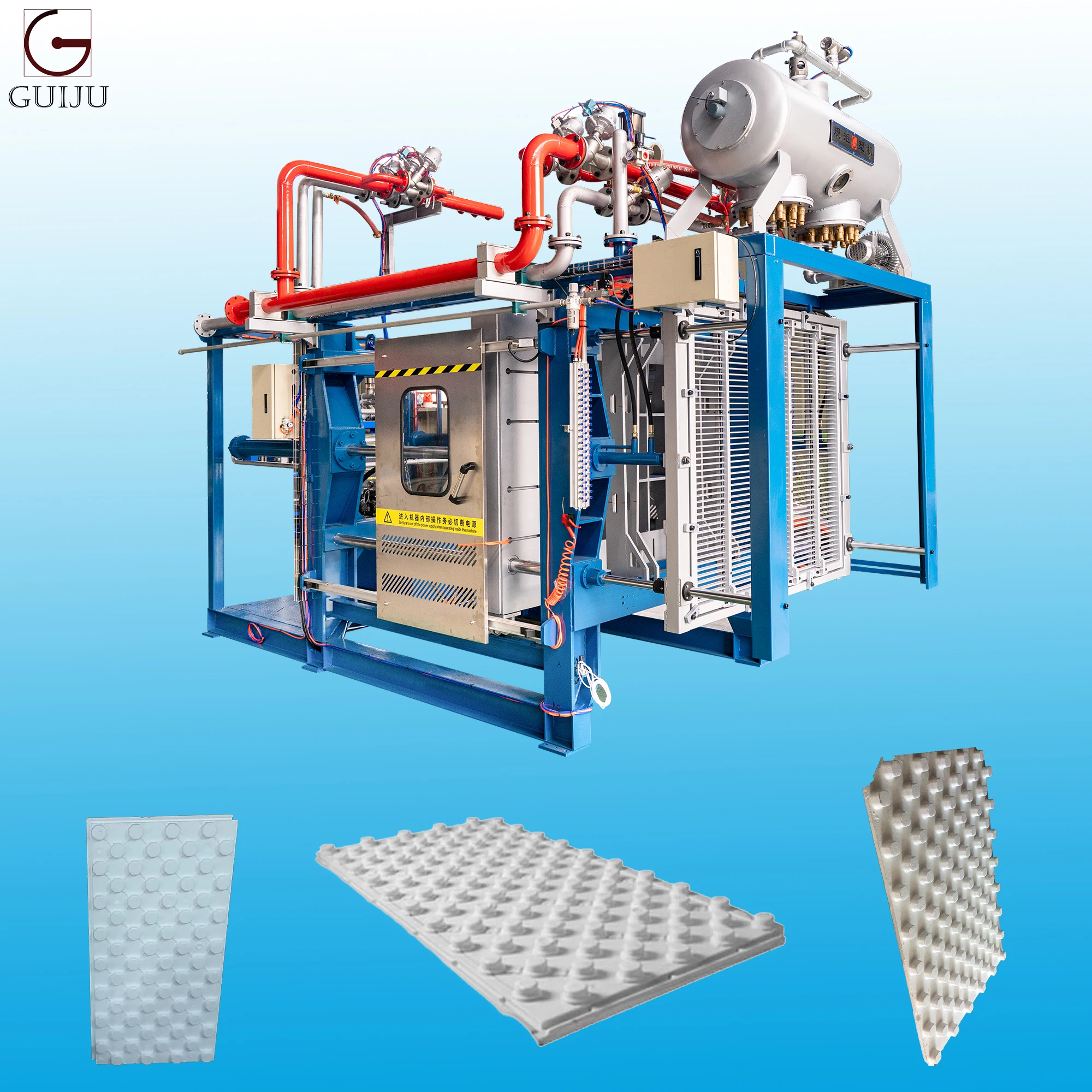

Hot Selling EPS Vacuum Cooling Block Molding Machine Easy to Operate Foam Board Panel Making Machine

- Overview

- Recommended Products

Guiju

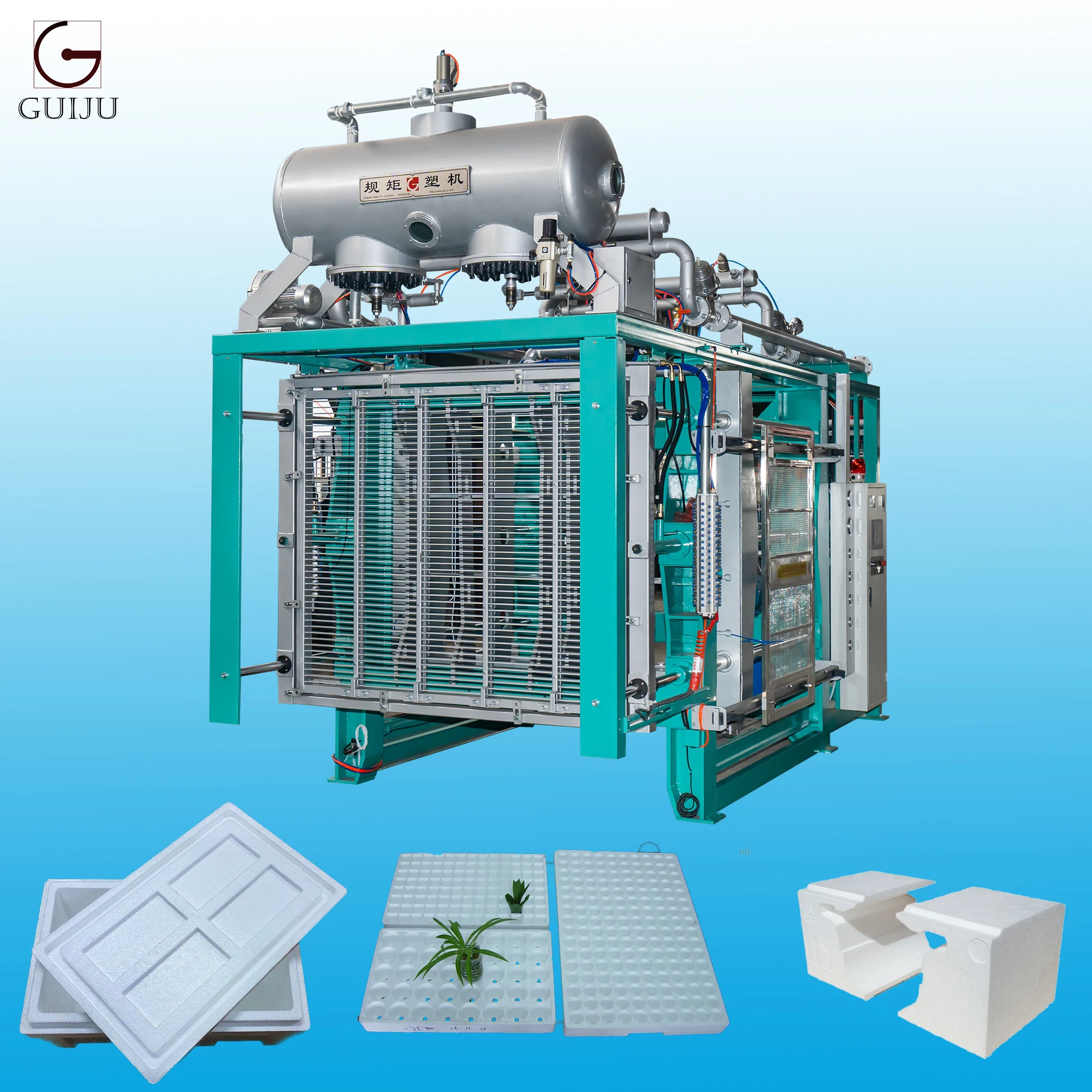

Introducing the EPS Vacuum Cooling Block Molding Machine, the ultimate solution for creating foam board panels with ease and efficiency. This hot selling machine is designed to streamline the process of making foam panels, making it a must-have tool for any production facility.

The Guiju EPS Vacuum Cooling Block Molding Machine is equipped with advanced technology that allows for quick and precise molding of foam blocks. The vacuum cooling feature ensures that the foam panels cool evenly and quickly, resulting in high-quality finished products every time.

One of the standout features of this machine is its ease of operation. With simple controls and intuitive design, even novice operators can quickly learn how to use the machine effectively. This means that production can run smoothly without the need for extensive training or experience.

The efficiency of the guiju EPS Vacuum Cooling Block Molding Machine is unmatched. It can produce a large number of foam board panels in a short amount of time, making it ideal for high-volume production environments. This machine is also designed to be durable and reliable, ensuring that it will continue to perform consistently over time.

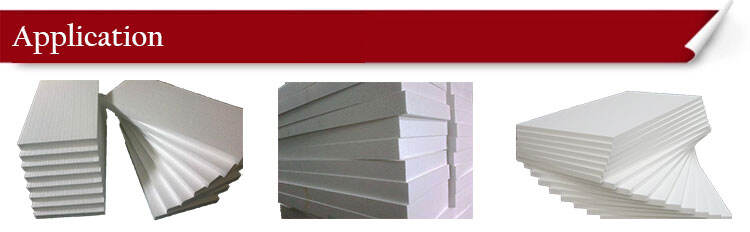

In addition to its exceptional performance, the Guiju EPS Vacuum Cooling Block Molding Machine is also highly versatile. It can accommodate a variety of foam materials and sizes, allowing for flexibility in production. This machine is perfect for creating foam panels for a wide range of applications, from insulation to packaging.

With its combination of efficiency, ease of use, and versatility, the Guiju EPS Vacuum Cooling Block Molding Machine is a must-have for any production facility looking to streamline their foam panel production process. Invest in this top-selling machine today and watch your productivity soar.

Automatic EPS block molding machine with vacuum cooling

Main feature:

Technical data:

model |

unit |

GJ-BZ-2000 |

GJ-BZ-3000 |

GJ-BZ-4000 |

GJ-BZ-6000 |

|||

mould Cavity Size |

mm |

2040*1240*1040 |

3050*1240*1040 |

4070*1240*1040 |

6090*1240*1040 |

|||

foam block size |

mm |

2000*1200*1000 |

3000*1200*1000 |

4000*1200*1000 |

6000*1200*1000 |

|||

steam system

|

inlet size |

mm |

DN100 |

DN100 |

DN150 |

DN150 |

||

inlet pressure |

bar |

5---8 |

5---8 |

5---8 |

5---8 |

|||

consumption |

kg/cycle |

30-50 |

40-70 |

55-85 |

70-130 |

|||

compressed air system

|

inlet size |

mm |

DN50 |

DN50 |

DN65 |

DN65 |

||

inlet pressure |

bar |

5-8 |

5-8 |

5-8 |

5-8 |

|||

consumption |

m³/cycle |

1-1.5 |

1.5-1.8 |

1.8-2 |

2-2.3 |

|||

injector sizeInjector

|

injector NO. |

8pcs |

10pcs |

16pcs |

22pcs |

|||

injector size |

DN80 |

DN80 |

DN80 |

DN80 |

||||

drainage pipe |

mm |

DN125 |

DN125 |

DN150 |

DN150 |

|||

vacuum drainage |

mm |

DN80 |

DN100 |

DN125 |

DN125 |

|||

condensation drainage |

mm |

DN100 |

DN125 |

DN125 |

DN125 |

|||

cycle Time (15g/l) |

min/cycle |

3 |

4 |

5 |

6 |

|||

vacuum pump power |

kw |

5.5kw*2 |

5.5kw*2 |

11kw*2 |

11kw*2 |

|||

installed Power |

kw |

20.5 |

22 |

33 |

33 |

|||

overall Size |

mm |

7500*3200*3500 |

5500*3200*3500 |

11000*3200*3500 |

13000*3200*3500 |

|||

machine weight |

kg |

6000 |

8000 |

10000 |

12000 |

|||