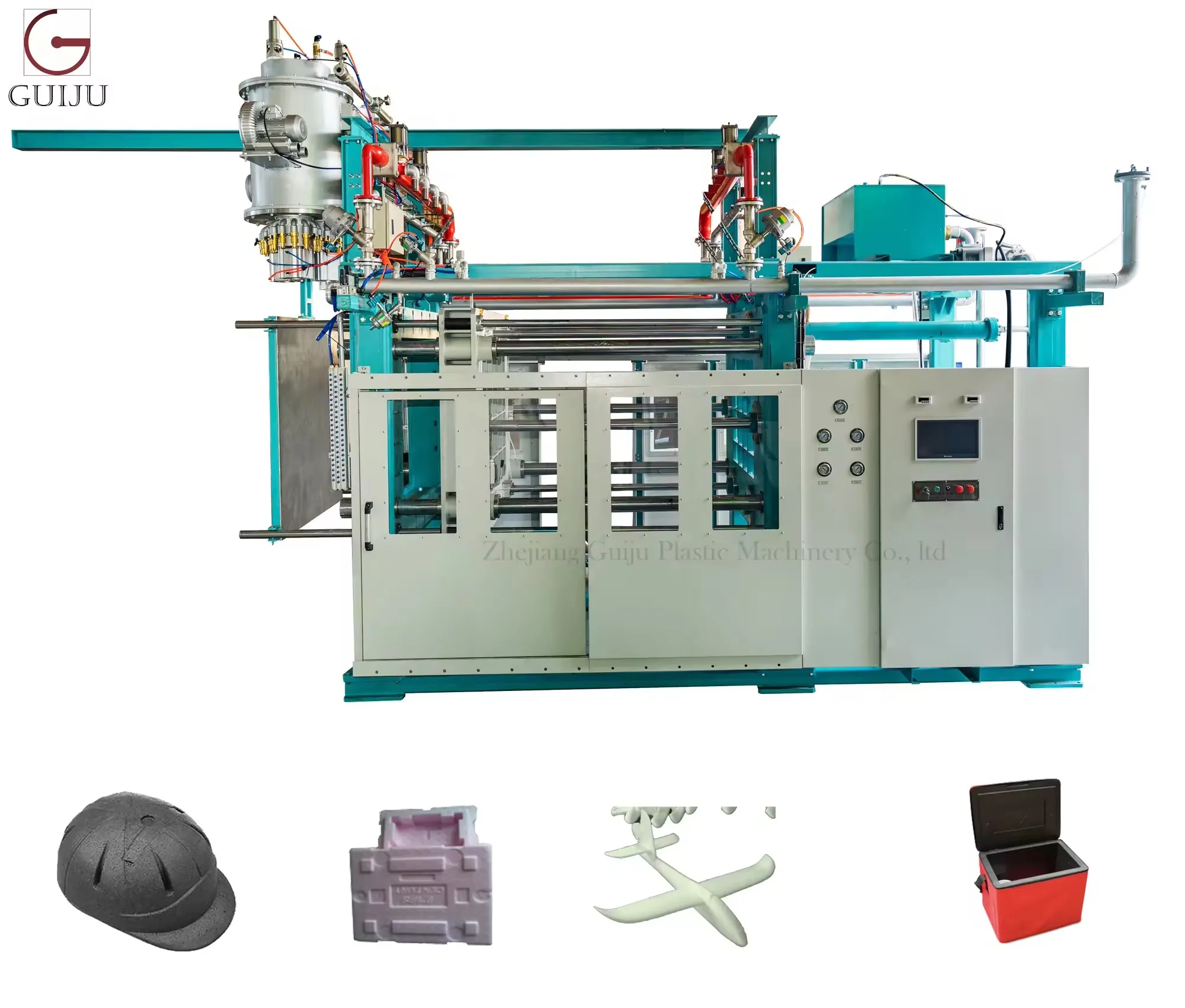

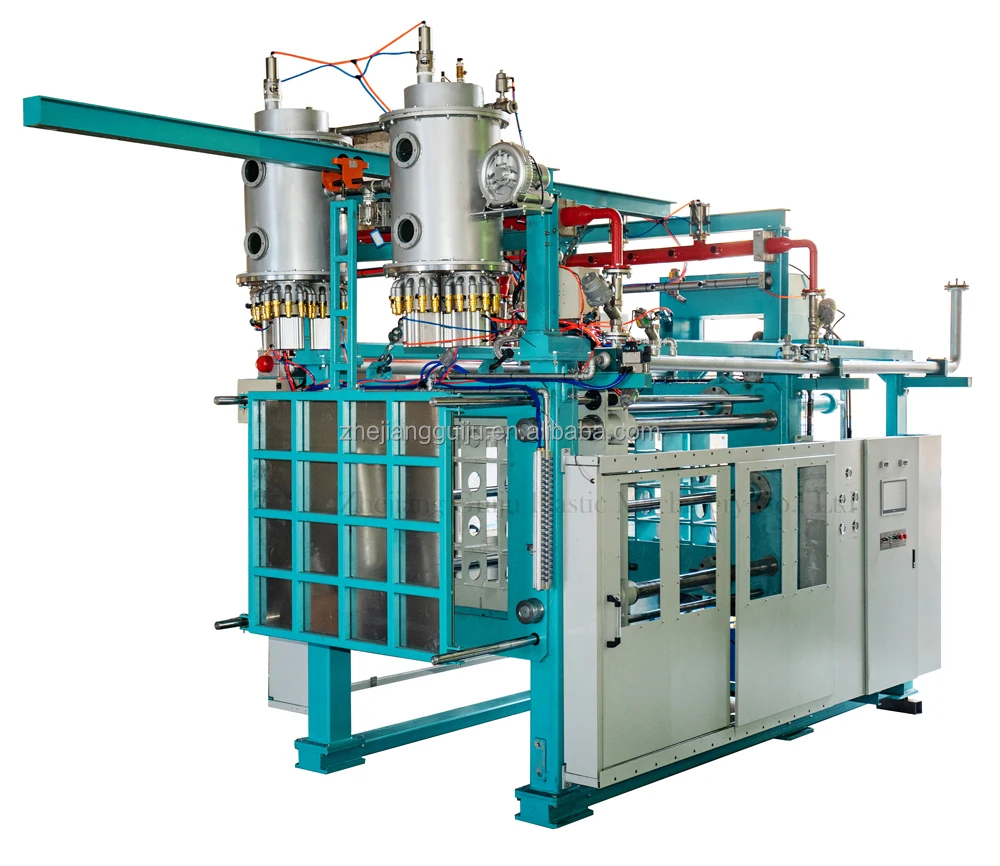

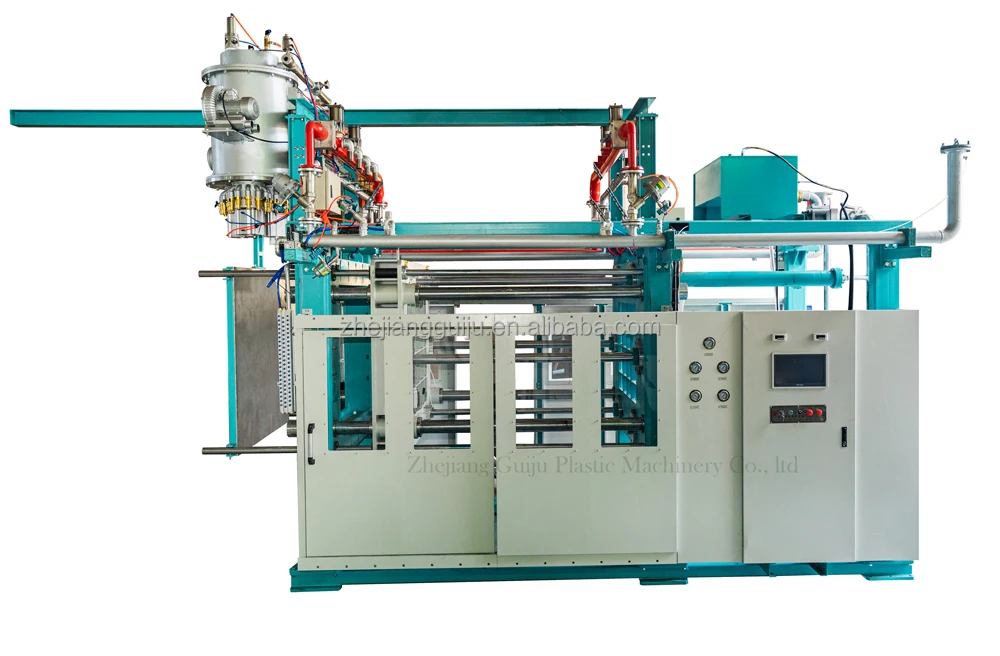

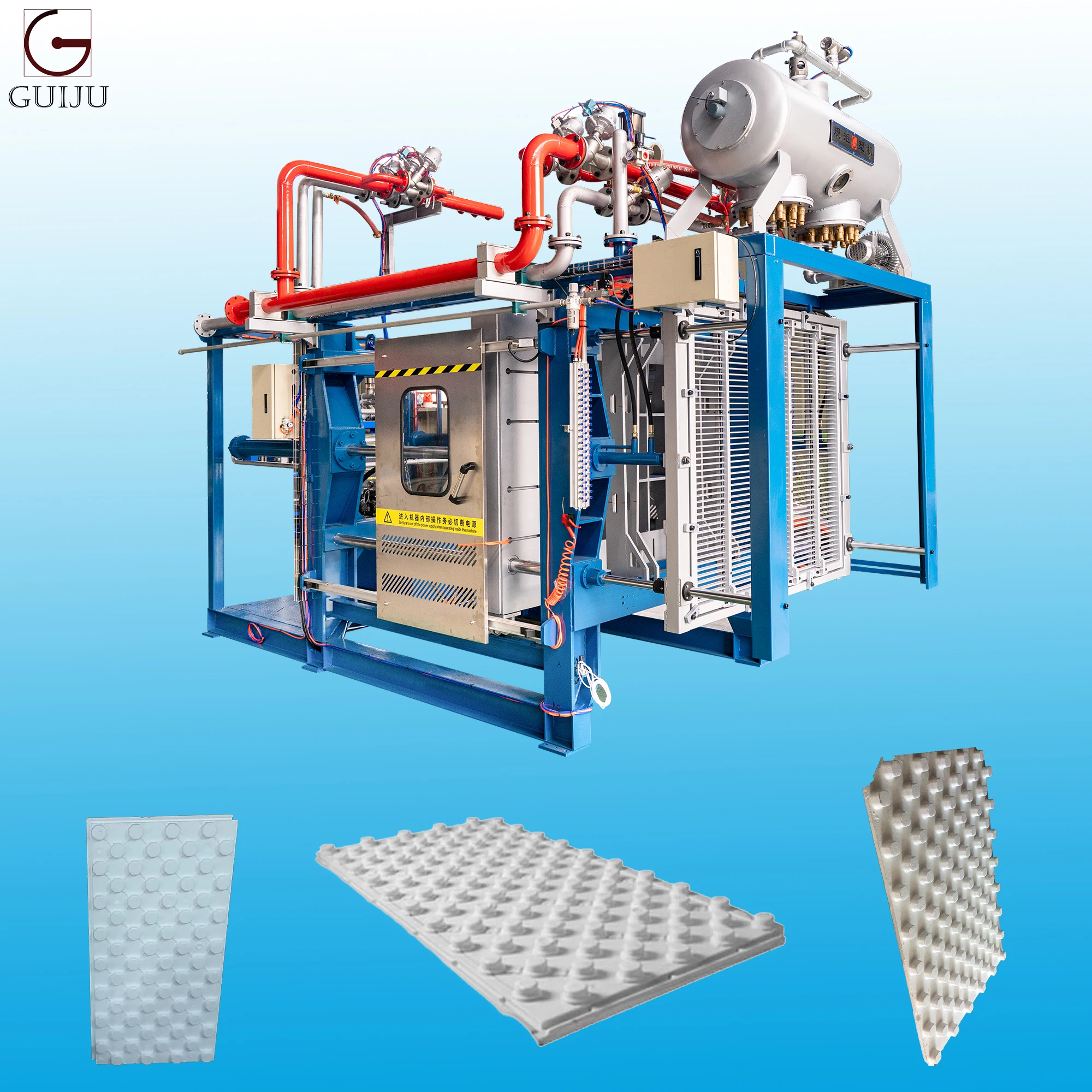

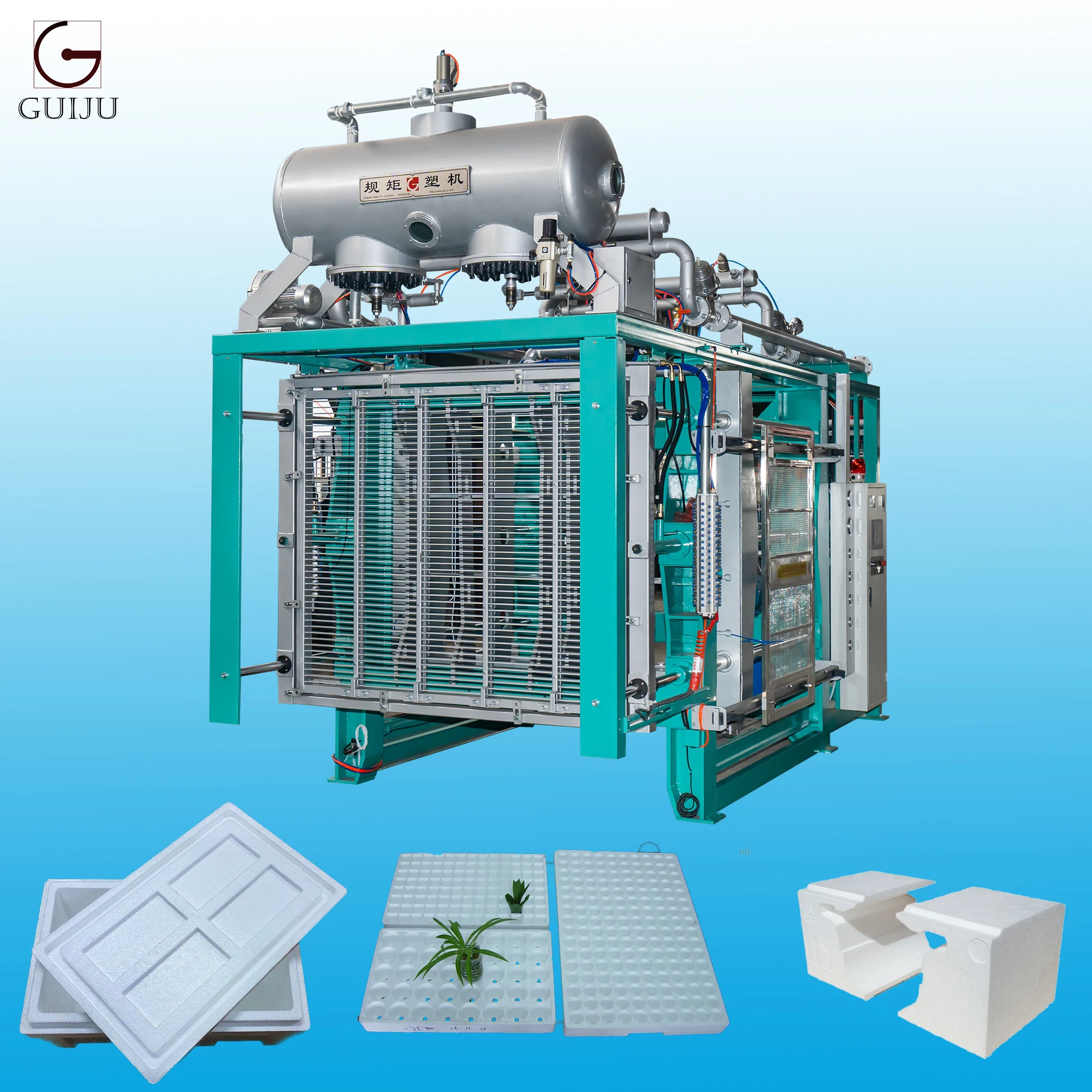

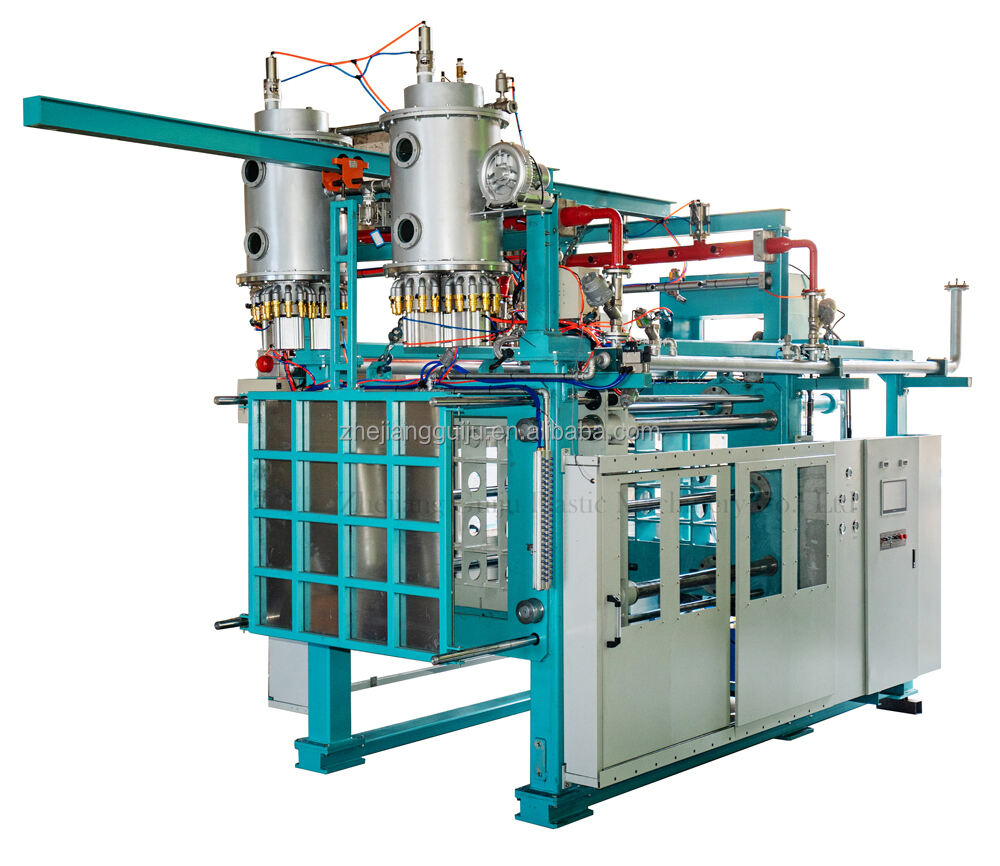

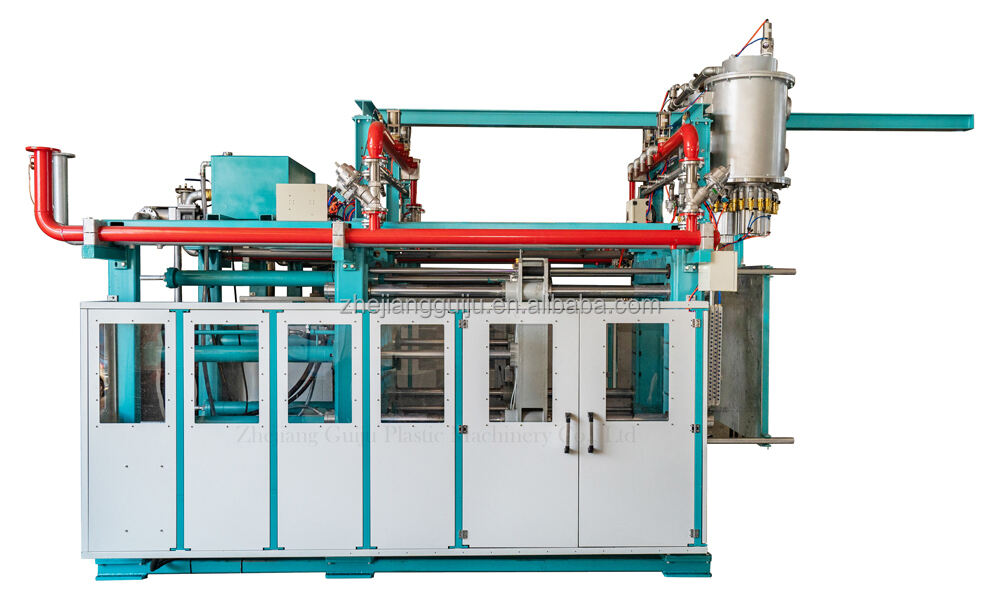

Professional Manufacturer Direct Sale High Quality Automatic Epp Foam Surfboard Shape Molding Machine

- Overview

- Recommended Products

Top sales automatic EPP shape molding machine with vacuum cooling

Main feature:

1. Solid machine frame in welded construction made of steel profiles 2. Stable mould closing unit with fixed and moving steam chamber on 4 tie bars 3. Steel steam chambers with corrosion protection by thermally applied aluminum coating 4. Optimal steam distribution over total width of steam chamber 5. Quick movements due to directly acting hydraulic with symmetrical introduction of the closing force 6. Auxiliary hydraulic system energy saving mode locking ability enhancement 7. High accuracy by precise position control and mechanic synchronizing device for movable steam chamber 8. Open and clear construction with best accessibility to aggregates and control units;as well as for mould change and handling systems 9. Single vacuum system with condenser 10. Short cycle times by means of Spaciously dimensioned valves and supply leads 11. Volumetric water dosing for high repeat accuracy during mould cooling 12. Equipment control adopts full digital proportional control, precise control of production of energy consumption

Technical data

|

Subjects

|

Unit

|

GJIT-813P

|

GJIT-1210P

|

GJIT-1214P

|

GJIT-1315P

|

GJIT-1318P

|

||

|

steam room size

|

mm

|

800×1300

|

1200×1400

|

1300×1500

|

1200×1400

|

1200×1700

|

||

|

Max. product size

|

mm

|

700×1200

|

900×1100

|

1100×1300

|

1200×1400

|

1200×1700

|

||

|

Max. stroke

|

mm

|

1250

|

1250

|

1250

|

1250

|

1250

|

||

|

Max. thickness size

|

mm

|

350

|

350

|

350

|

350

|

350

|

||

|

Max. steam pressure

|

bar

|

8

|

8

|

8

|

8

|

8

|

||

|

Lock mold pressure

|

KN

|

645

|

645

|

1035

|

1035

|

1200

|

||

|

filling gun interface

|

2X16 G1

|

2X16 G1

|

2X16 G1

|

2X25 G1

|

2X25 G1

|

|||

|

material inlet

|

inch

|

R2’’/DN50

|

R2’’/DN50

|

R2’’/DN50

|

R2’’/DN50

|

R2’’/DN50

|

||

|

steam inlet

|

inch

|

R4’’/DN100

|

R4’’/DN100

|

R4’’/DN100

|

R4’’/DN100

|

R4’’/DN125

|

||

|

air inlet

|

inch

|

R2’’/DN65& R1-1/2’’/DN50

|

R2’’/DN65& R1-1/2’’/DN50

|

R2’’/DN65& R1-1/2’’/DN50

|

R2’’/DN65& R1-1/2’’/DN50

|

R2’’/DN65& R1-1/2’’/DN50

|

||

|

cooling water inlet

|

inch

|

R2-1/2’’/DN80

|

R2-1/2’’/DN80

|

R2-1/2’’/DN80

|

R2-1/2’’/DN80

|

R2-1/2’’/DN80

|

||

|

main drainage inlet

|

inch

|

R6’’/DN150

|

R6’’/DN150

|

R6’’/DN150

|

R6’’/DN150

|

R6’’/DN150

|

||

|

condenser drain

|

inch

|

R3’’/DN80

|

R3’’/DN80

|

R3’’/DN80

|

R3’’/DN80

|

R3’’/DN80

|

||

|

control screen

|

15 inch touch screen

|

15 inch touch screen

|

15 inch touch screen

|

15 inch touch screen

|

15 inch touch screen

|

|||

|

Hydraulic motor

|

kw

|

7.5kw-50Hz

|

7.5kw-50Hz

|

7.5kw-50Hz

|

7.5kw-50Hz

|

7.5kw-50Hz

|

||

|

vacuum pump

|

kw

|

5.5kw-50Hz

|

5.5kw-50Hz

|

5.5kw-50Hz

|

5.5kw-50Hz

|

5.5kw-50Hz

|

||

|

suction material fan

|

kw

|

1.5kw-50Hz

|

1.5kw-50Hz

|

1.5kw-50Hz

|

1.5kw-50Hz

|

1.5kw-50Hz

|

||

|

overall size

|

mm

|

5200X2800X4300

|

5200X2800X4300

|

5200x2900x4350

|

5300x3000x4920

|

5300x3375x4920

|

||

|

machine weight

|

kg

|

About 9000

|

About 9500

|

About 10500

|

About 11300

|

About 11800

|

||